50000 Chicken Layer Farm Technology: A Comprehensive Guide to Modern Avian Farming Techniques

Time : 2025-06-30

The poultry industry has seen tremendous growth over the past few decades, and chicken layer farming is no exception. With advancements in technology, large-scale chicken layer farms can now achieve maximum efficiency, productivity, and sustainability. This article will explore the latest technology used in a 50,000 chicken layer farm, providing a comprehensive guide to modern avian farming techniques.

Introduction to Large-Scale Chicken Layer Farming

Large-scale chicken layer farming involves the production of eggs by a large number of hens on a commercial scale. These farms typically consist of thousands to tens of thousands of chickens, which are raised in controlled environments to ensure optimal egg production. The size of a chicken layer farm can range from a few thousand birds to over 100,000 birds, and managing such a farm requires advanced technology and expertise.

Environmental Control Systems

One of the key aspects of managing a 50,000 chicken layer farm is maintaining an ideal environment for the birds. Environmental control systems are crucial in ensuring the health, growth, and overall welfare of the chickens. Here are some of the essential components of such a system:

- Temperature Regulation: Automated systems monitor and control the temperature within the farm, keeping it within the optimal range for chicken production.

- Humidity Control: Sufficient humidity is vital for the chickens, and the system can maintain the humidity level within the desired range.

- Air Circulation: Airflow systems are designed to distribute clean air evenly throughout the farm, providing an oxygen-rich environment for the chickens.

- Luminescent Control: Automatic lighting systems simulate the natural daylight cycle, optimizing the chickens’ health and egg production.

Feeding Technology

Feeding accounts for a significant portion of the total cost in chicken layer farming. To maximize efficiency and minimize waste, modern farming technology utilizes automated feeding systems. Here are some key features of these systems:

- Automated Feed Delivery: Feeders are programmed to dispense the precise amount of feed at set intervals, ensuring that the chickens receive the right balance of nutrients.

- Customized Rations: The systems can be adjusted to deliver different rations based on the chickens’ age, stage of production, and specific dietary requirements.

- Water Supply: Continuous water supply systems are integrated into the farm, ensuring that the chickens have access to clean water at all times.

Watering Systems

Water is crucial for the health and well-being of chickens, and an efficient watering system is essential for a 50,000 chicken layer farm. Modern systems include the following features:

- Automatic Waterers: The waterers are equipped with sensors that activate the water flow only when the chickens need it, reducing water waste.

- Filtering Systems: Water quality is maintained by filtering systems that remove impurities, providing clean water to the chickens.

- Monitoring and Maintenance: Automated monitoring systems alert farm managers to potential issues with the watering system, allowing for prompt maintenance and repair.

Health Management and Biosecurity

The health of chickens is paramount in the poultry industry. Modern farms implement advanced health management and biosecurity measures to prevent and control diseases. Here are some key aspects:

- Sanitization: Facilities are regularly sanitized to eliminate harmful pathogens and reduce the risk of disease.

- Monitoring and Testing: Health monitoring systems and regular testing are in place to identify and address any health issues promptly.

- Segregation and Biocontainment: The farm is divided into separate areas for different stages of production, minimizing the spread of disease.

Automated Egg Collection Systems

Manual egg collection is time-consuming and labor-intensive. Modern farming technology incorporates automated egg collection systems that streamline the process. These systems include:

- Egg Trays: Hens lay eggs into trays that are designed to prevent breakage and contamination.

- Conveyor Belts: Eggs are conveyed to collection points where they are collected, graded, and packaged for distribution.

- Sorting and Packaging: The systems can sort and package eggs based on size, weight, and quality, optimizing the supply chain.

Energy Efficiency and Sustainability

Energy efficiency and sustainabi lity are vital in the poultry industry. Modern 50,000 chicken layer farms implement various energy-saving measures, including:

lity are vital in the poultry industry. Modern 50,000 chicken layer farms implement various energy-saving measures, including:

- Solar Power: Solar panels can provide a significant portion of the farm’s energy needs, reducing electricity costs and environmental impact.

- LED Lighting: LED lighting systems consume less energy than traditional lighting, further reducing the farm’s carbon footprint.

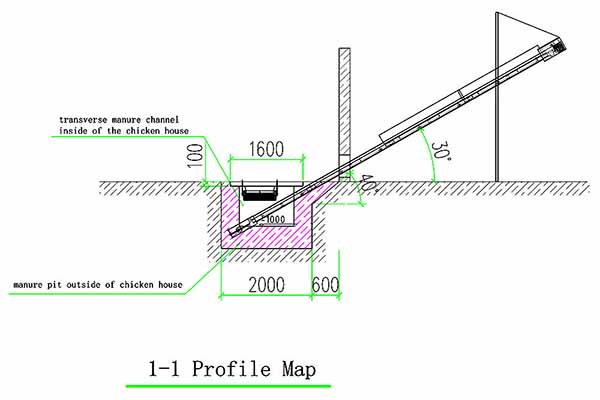

- Waste Management: Efficient waste management systems help reduce pollution and promote sustainable practices.

Conclusion

A 50,000 chicken layer farm requires advanced technology and expert management to achieve maximum efficiency, productivity, and sustainability. The environmental control systems, feeding technology, watering systems, health management, automated egg collection sy stems, and energy-efficient practices discussed in this article are essential for a successful modern avian farming operation.

stems, and energy-efficient practices discussed in this article are essential for a successful modern avian farming operation.