Recommended Automated Disinfection Equipment for Uganda Chicken Farms

Time : 2025-06-25

Chicken farming is a vital component of the agricultural sector in Uganda, contributing significantly to food security and economic growth. However, ensuring the health and productivity of poultry is paramount, and this is where automated disinfection equipment comes into play. This article provides a comprehensive guide to the recommended automated disinfection equipment for Uganda’s chicken farms, focusing on the latest technologies and practical considerations.

Understanding the Need for Automated Disinfection Equipment

Chicken farms are susceptible to various diseases that can lead to significant economic losses. Pathogens such as bacteria, viruses, and parasites can contaminate the environment, affecting the health of the birds and the quality of the eggs and meat produced. To mitigate these risks, it is crucial to implement effective disinfection protocols.

Disease Control and Biosecurity Measures

Automated disinfection equipment plays a pivotal role in disease control and biosecurity measures. By reducing the presence of pathogens in the farm environment, it helps prevent outbreaks and maintains the overall health of  the flock. This is particularly important in Uganda, where the poultry industry is rapidly growing and biosecurity is a major concern.

the flock. This is particularly important in Uganda, where the poultry industry is rapidly growing and biosecurity is a major concern.

Types of Automated Disinfection Equipment

There are several types of automated disinfection equipment suitable for Uganda’s chicken farms. Each has its unique advantages and is designed to address specific disinfection needs. The following are some of the recommended equipment:

1. Ultraviolet (UV) Disinfection Systems

UV disinfection systems use ultraviolet light to destroy the genetic material of microorganisms, rendering them harmless. These systems are effective against a wide range of pathogens, including bacteria, viruses, and fungi. UV lights can be installed in poultry houses, feed storage areas, and on conveyor belts to ensure continuous disinfection.

2. Chemical Disinfection Equipment

Chemical disinfection involves the use of disinfectants to kill pathogens. Automated systems can apply these chemicals in a controlled and efficient manner, reducing the risk of overuse and environmental contamination. Equipment such as spray systems and misters can be used to apply disinfectants to the poultry house, equipment, and birds.

3. High-Pressure Water Jet Systems

High-pressure water jet systems are effective for cleaning and disinfecting surfaces. These systems use high-pressure water to remove dirt, debris, and pathogens from the farm environment. They are particularly useful for cleaning feeders, waterers, and other equipment that come into contact with the birds.

4. Electrostatic Sprayers

Electrostatic sprayers use an electric charge to make the disinfectant particles adhere to surfaces more effectively. This ensures a more uniform application and reduces the amount of chemical used. These sprayers are ideal for disinfecting large areas quickly and efficiently.

Choosing the Right Equipment for Uganda Chicken Farms

Selecting the appropriate automated disinfection equipment for Uganda’s chicken farms requires careful consideration of several factors:

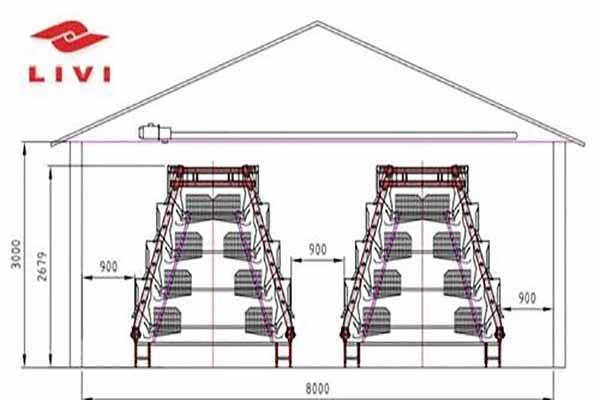

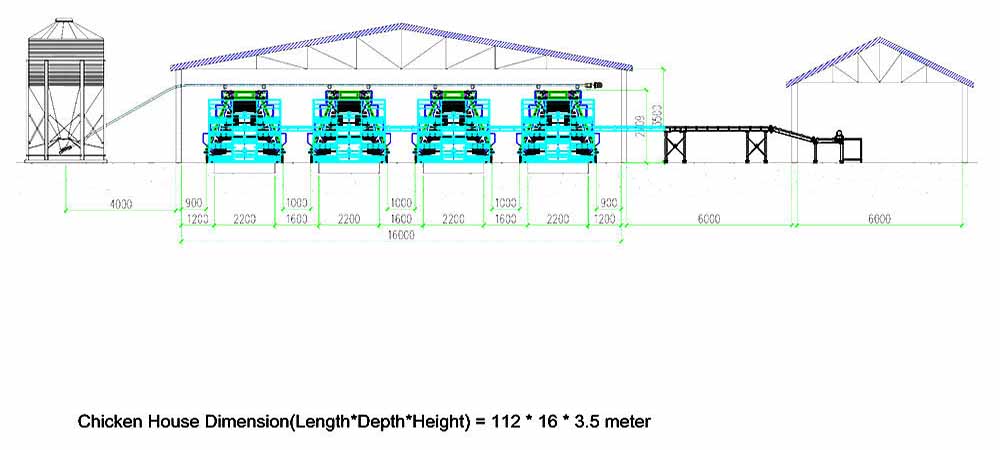

1. Farm Size and Layout

The size and layout of the farm wi ll determine the scale of the disinfection equipment needed. Larger farms may require multiple systems to cover all areas effectively.

ll determine the scale of the disinfection equipment needed. Larger farms may require multiple systems to cover all areas effectively.

2. Type of Disinfection Method

The choice of disinfection method should align with the specific needs of the farm. For example, UV systems are ideal for continuous disinfection, while chemical sprayers are better for targeted applications.

3. Environmental Considerations

Uganda’s climate and environmental conditions should be taken into account when selecting disinfection equipment. Systems that are durable and can withstand the local weather conditions are essential.

4. Cost and Efficiency

The cost of the equipment, including installation and maintenance, should be weighed against the expected benefits. Efficient systems that provide long-term savings and improved biosecurity are preferable.

Implementation and Maintenance

Implementing automated disinfection equipment is just the first step. Regular maintenance and proper operation are crucial for the systems to remain effective. Training farm staff on the correct use of the equipment and establishing a maintenance schedule are essential for long-term success.

Conclusion

Automated disinfection equipment is a vital tool for Uganda’s chicken farms, helping to maintain biosecurity and prevent disease outbreaks. By carefully selecting the right equipment and implementing proper maintenance protocols, farmers can ensure the health and productivity of their flocks. This guide provides a comprehensive overview of the recommended equipment and considerations for Uganda’s chicken farms, contributing to a more robust and sustainable poultry industry.