Tanzania’s 10,000 Chicken Automatic Feeding System: Revolutionizing Poultry Farming

Time : 2025-06-25

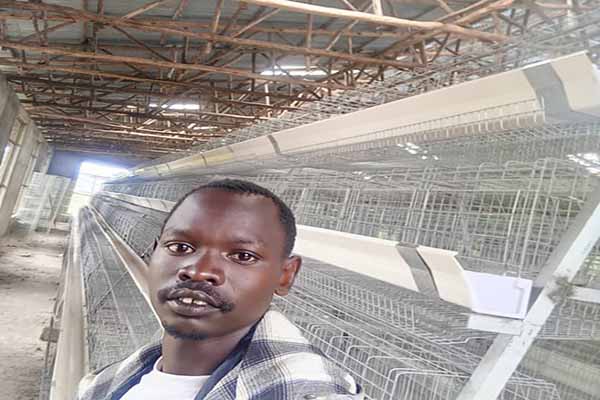

The poultry industry in Tanzania has seen remarkable growth over the past decade. With the increasing demand for poultry products, modern farming techniques are becoming essential for sustainable production. One such innovation is the implementation of an automatic feeding system for a 10,000-chicken farm. This article delves into the details of this system, exploring its design, benefits, and the impact it has on poultry farming in Tanzania.

Understanding the Need for an Automatic Feeding System

Traditional poultry farming methods in Tanzania often rely on manual feeding, which is both time-consuming and labor-intensive. Feeding chickens manually can lead to inconsistencies in nutrition, increased labor costs, and even the potential for disease transmission. To address these challenges, the installation of an automatic feeding system for a 10,000-chicken farm was a strategic decision.

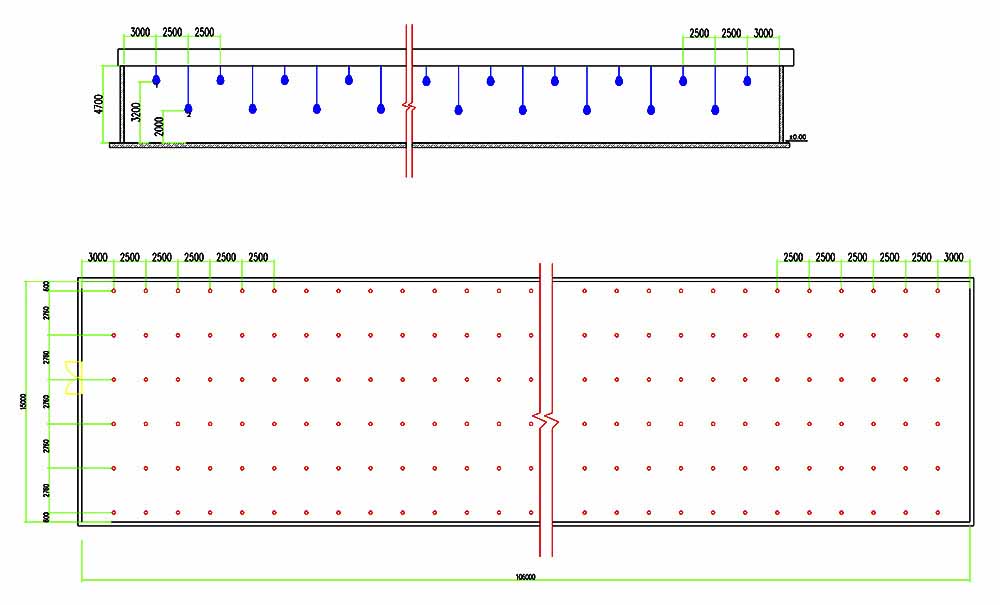

Design and Components of the 10,000 Chicken Automatic Feeding System

The automatic feeding system for the 10,000-chicken farm in Tanzania is a sophisticated piece of equipment that integrates various components to ensure efficient and accurate feeding. Here’s a breakdown of the key components:

- Feed Hopper: This is where the feed is stored. It can hold a significant amount of feed, reducing the frequency of refilling.

- Feeding Auger: The auger is responsible for transporting feed from the hopper to the feeding stations. It ensures a steady flow of feed.

- Feeding Stations: These are located in the chicken coops where the chickens can access the feed. The system is designed to deliver feed to each station simultaneously, ensuring uniform distribution.

- Control Panel: This panel allows the farmer to monitor and control the feeding process. It includes settings for the feeding rate, duration, and pause functionality.

- Electrical Supply: The system requires a reliable power source. In areas with inconsistent electricity, solar-powered solutions can be used to ensure continuous operation.

The system is d esigned to be scalable, allowing for adjustm

esigned to be scalable, allowing for adjustm ents to accommodate varying chicken populations and different feeding requirements.

ents to accommodate varying chicken populations and different feeding requirements.

Benefits of the Automatic Feeding System

The implementation of the 10,000-chicken automatic feeding system in Tanzania offers several significant benefits:

- Improved Efficiency: The system eliminates the need for constant manual feeding, freeing up time for the farmer to focus on other aspects of farm management.

- Uniform Nutrition: With precise control over the feeding process, the chickens receive a consistent and balanced diet, leading to better health and productivity.

- Reduced Labor Costs: Automating the feeding process reduces the need for additional labor, thus cutting down on operational costs.

- Reduced Risk of Disease: Manual feeding can lead to cross-contamination. The automatic system minimizes this risk by ensuring a clean and hygienic feeding environment.

- Increased Production: Well-nourished chickens tend to grow faster and produce more eggs, leading to higher yields.

Installation and Maintenance

Installing an automatic feeding system requires careful planning and execution. The following steps are typically involved:

- Site Assessment: The suitability of the location for the system is assessed, including the availability of power and space.

- Equipment Selection: The appropriate feeding system is chosen based on the farm’s size and requirements.

- Installation: The system is installed according to the manufacturer’s specifications, ensuring all components are properly aligned and secured.

- Training: The farmer and staff are trained on how to operate and maintain the system.

- Regular Maintenance: Regular maintenance is crucial to keep the system running smoothly and to prevent downtime.

Conclusion

The introduction of the 10,000-chicken automatic feeding system in Tanzania marks a significant step forward in modern poultry farming. By automating the feeding process, the system has improved efficiency, reduced costs, and enhanced the overall productivity of the farm. As the poultry industry continues to grow in Tanzania, such innovations are set to play a pivotal role in ensuring sustainable and profitable operations.