Commercial Poultry Cage System for 25000 Birds: Design, Efficiency, and Maintenance

Time : 2025-06-26

The commercial poultry industry has seen significant advancements in the design and implementation of poultry cage systems. For operations housing 25,000 birds, a well-designed commercial poultry cage system is crucial for optimal performance, health, and profitability. This article delves into the intricacies of a commercial poultry cage system designed for 25,000 birds, covering aspects such as design, efficiency, and maintenance.

Design Considerations for a 25000 Bird Commercial Poultry Cage System

When designing a commercial poultry cage system for 25,000 birds, several key factors must be considered to ensure the system is efficient, hygienic, and sustainable.

Space Allocation

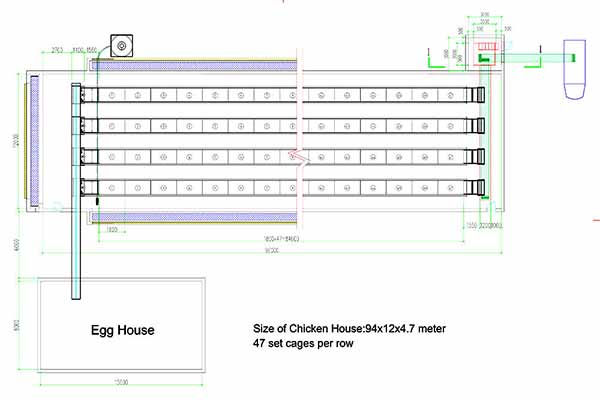

Proper space allocation is vital for the well-being of the birds. Each bird requires a minimum of 0.3 square meters of space. For 25,000 birds, this translates to approximately 7,500 square meters of floor space. The design should allow for easy movement of the birds within the cage, minimizing stress and promoting health.

Material Selection

The choice of material for the cage system is critical. High-quality, corrosion-resistant materials such as stainless steel or galvanized steel are ideal. These materials ensure durability and longevity, reducing maintenance costs and the risk of contamination.

Automated Feeding and Watering Systems

Automated feeding and watering systems are essential for a commercial poultry operation. These systems ensure consistent and efficient delivery of feed and water, reducing labor costs and minimizing waste. For a 25,000 bird operation, a robust automated system capable of handling large volumes is necessary.

Environmental Control

Environmental control is crucial for maintaining optimal conditions for the birds. A well-designed ventilation system, temperature control, and lighting are ess ential. The system should be capable of adjusting these parameters automatically to maintain a stable environment throughout the year.

ential. The system should be capable of adjusting these parameters automatically to maintain a stable environment throughout the year.

Efficiency of the Commercial Poultry Cage System

The efficiency of a commercial poultry cage system for 25,000 birds is a multifaceted concept, encompassing operational, economic, and environmental aspects.

<h3 >Operational Efficiency

>Operational Efficiency

Operational efficiency is achieved through the integration of automated systems that streamline processes such as feeding, watering, and waste management. These systems reduce labor requirements and improve overall productivity.

Economic Efficiency

Economic efficiency is vital for the profitability of a commercial poultry operation. A well-designed cage system reduces energy consumption, waste, and maintenance costs. Additionally, efficient use of space allows for increased bird density without compromising on animal welfare.

Environmental Efficiency

Environmental efficiency is achieved through sustainable design and operation. The system should minimize waste, use renewable energy sources when possible, and contribute to a reduced carbon footprint.

Maintenance of the Commercial Poultry Cage System

Regular maintenance is essential to ensure the longevity and efficiency of a commercial poultry cage system for 25,000 birds.

Preventative Maintenance

Preventative maintenance involves regular inspections and cleaning of the system. This includes checking for any signs of wear and tear, tightening loose bolts, and ensuring that all components are functioning correctly. Regular cleaning helps prevent the buildup of bacteria and reduces the risk of disease outbreaks.

Repair and Replacement

When wear and tear become evident, prompt repair and replacement of components are necessary. Delaying repairs can lead to more extensive damage and increased downtime.

Training and Documentation

Proper training of staff on the operation and maintenance of the system is crucial. Additionally, maintaining detailed documentation of maintenance activities and system performance can help identify trends and areas for improvement.

Conclusion

A commercial poultry cage system for 25,000 birds requires careful design, efficient operation, and thorough maintenance to ensure optimal performance and profitability. By considering space allocation, material selection, automated systems, environmental control, and regular maintenance, poultry producers can create a sustainable and successful operation.