Optimizing Chicken Farming with a 20,000 Layer Chicken Farming House: A Comprehensive Guide

Time : 2025-06-27

Chicken farming, as one of the most profitable agricultural enterprises, requires meticulous planning and execution. In this article, we delve into the intricacies of setting up a 20,000-layer chicken farming house, focusing on the equipment, management, and best practices to ensure a successful and sustainable operation. This comprehensive guide will provide valuable insights for both seasoned farmers and newcomers to the industry.

Understanding the 20,000 Layer Chicken Farming House

A 20,000-layer chicken farming house is a large-scale facility designed to house and manage a significant number of laying hens. These houses are engineered to maximize efficiency and minimize costs while ensuring the health and productivity of the chickens. Let’s explore the key components and considerations for such a venture.

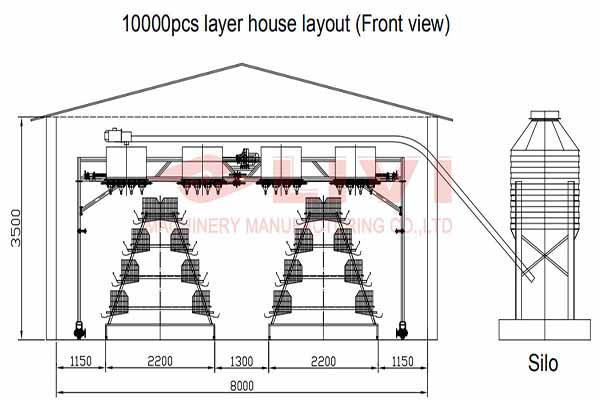

Design and Layout

The design of a 20,000-layer chicken farming house is crucial for optimal performance. It should incorporate the following elements:

- Space Allocation: Each chicken should have adequate space to move around, reducing the risk of injury and disease. Typically, a space of about 0.6 to 0.8 square feet per bird is recommended.

- Lighting: Natural sunlight is beneficial for chickens, but artificial lighting can be used to simulate natural daylight cycles, promoting egg production.

- Ventilation: Proper ventilation is essential to maintain air quality and temperature. Exhaust fans and intake vents should be strategically placed to ensure a continuous flow of fresh air.

- Manure Management: An efficient manure management system is necessary to handle the waste produced by a large number of chickens. This may include solid manure separation and composting facilities.

Equipment for a 20,000 Layer Chicken Farming House

The equipment used in a 20,000-layer chicken farming house should be robust, reliable, and designed for high capacity. Here are some of the key pieces of equipment:

Feeders and Waterers

Automated feeders and waterers are essential for consistent and efficient feeding and hydration. They should be capable of feeding and watering up to 20,000 birds without interruption.

- Feeders: High-capacity feeders with automated systems to control the flow of feed.

- Waterers: Automatic drinkers that provide a constant supply of clean water to the chickens.

Environmental Control Systems

Environmental control systems are critical for maintaining the ideal conditions for chickens. These systems include:

- Heating and Cooling: To keep the chickens comfortable in various weather conditions.

- Humidity Control: To maintain the appropriate humidity levels to prevent disease and optimize egg production.

- Automated Lighting: To simulate natural light cycles for better health and productivity.

Monitoring and Management Equipment

Monitoring and management equipment are crucial for keeping track of the flock’s health and productivity. These include:

- Environmental Sensors: To continuously monitor temperature, humidity, and other environmental parameters.

- Health Monitoring Systems: To detect early signs of illness or disease in the flock.

- Production Data Tracking: To record and analyze egg production and other performance metrics.

Management Strategies for a 20,000 Layer Chicken Farming House

Effective management is essential for the success of a 20,000-layer chicken farming house. Here are some key strategies:

Health and Welfare

Ensuring the health and welfare of the chickens is paramount. This includes:

- Regular Health Checks: Regular veterinary inspections and vaccinations to prevent disease.

- Comfortable Living Conditions: Maintaining clean, comfortable living conditions to prevent stress and disease.

- Proper Nutrition: Providing a balanced diet to optimize growth and egg production.

Efficient Manure Management

Proper manure management is crucial for environmental sustainability and biosecurity. Consider:

- Manure Separation: Separating solid and liquid manure to facilitate more efficient handling and disposal.

- Composting: Composting solid manure to produce organic fertilizer for agricultural use.

Staff Training and  Maintenance

Maintenance

Well-trained staff and regular equipment maintenance are essential for smooth operation:

- Staff Training: Ensuring that all staff are trained in chicken farming best practices and biosecurity protocols.

- Equipment Maintenance: Regular maintenance of all equipment to prevent downtime and ensure optimal performance.

Conclusion

Setting up a 20,000-layer chicken farming house is a significant investment that requires careful planning and execution. By focusing on the right equipment, efficient management strategies, and prioritizing the health and welfare of the chickens, farmers can create a successful and sustainable operation. This guide provides a comprehensive overview of the key considerations for anyone looking to enter or expand in the large-scale chicken farming industry.