Automatic Egg Collection Systems for Poultry: Enhancing Efficiency and Sanitation in the Industry

Time : 2025-06-30

In the modern poultry industry, the efficiency and hygiene of egg collection are crucial for maintaining high-quality produce and ensuring the health of both the birds and the workers. Automatic egg collection systems have revolutionized the process, providing a solution that is both practical and professional. This article delves into the intricacies of these systems, exploring their design, implementation, and benefits.

Understanding Automatic Egg Collection Systems

Automatic egg collection systems are designed to streamline the process of gathering eggs from poultry houses. These systems utilize advanced technology to detect, collect, and transport eggs with minimal human intervention. By automating this task, poultry farmers can significantly reduce labor costs and improve overall operational efficiency.

Design Principles

The design of automatic egg collection systems is based on several key principles:

- Accuracy: The system must accurately detect eggs and distinguish them from other objects in the poultry environment.

- Speed: The collection process should be rapid to minimize the risk of eggs becoming dirty or damaged.

- Sanitation: The system must be designed to prevent cross-contamination and maintain high levels of hygiene.

- Flexibility: The system should be adaptable to different poultry species and laying densities.

Key Components of Automatic Egg Collection Systems

Automatic egg collection systems consist of several critical components, each playing a vital role in the overall functionality:

Egg Detection Sensors

Egg detection sensors are the core of the system. These sensors use various technologies, such as infrared, visible light, or sound waves, to identify eggs. They must be sensitive enough to detect eggs of different sizes and colors while ignoring other debris or objects in the poultry house.

Egg Conveyance Mechanisms

Once detected, eggs are conveyed to a collection point. This can be achieved through a variety of mechanisms, including conveyor belts, vacuum systems, or mechanical arms. The conveyance system must be gentle to prevent egg damage and efficient to ensure a continuous flow of eggs.

Sorting and Washing Facilities

After collection, eggs typically undergo sorting and washing. Sorting ensures that eggs are graded based on size and quality, while washing removes any dirt or contaminants. Automatic systems may incorporate conveyors, sorters, and water sprays to facilitate this process.

Transportation Systems

Transportation systems are responsible for moving eggs from the collection point to storage or packaging areas. This can be done using conveyors, bins, o r automated guided vehicles (AGVs). The goal is to minimize handling and maintain the integrity of the eggs throughout the process.

r automated guided vehicles (AGVs). The goal is to minimize handling and maintain the integrity of the eggs throughout the process.

Implementation Considerations

Implementing an automatic egg collection system requires careful planning and consideration of several factors:

Integration with Existing Infrastructure

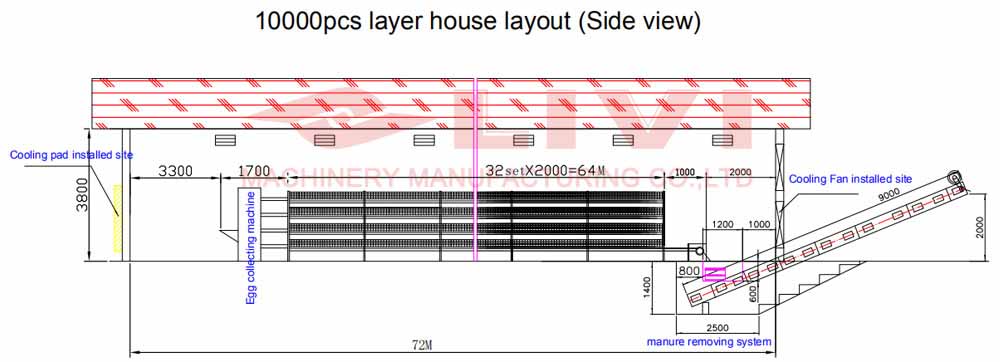

When integrating an automatic egg collection system, it’s essential to ensure compatibility with existing poultry house infrastructure, such as feeders, waterers, and ventilation systems.

Environmental Conditions

Conditions

The poultry house environment can significantly impact the performance of an automatic egg collection system. Factors such as temperature, humidity, and dust levels must be taken into account during the design and implementation stages.

Training and Support

Proper training for the farm staff is crucial for the successful operation of an automatic egg collection system. Additionally, ongoing support and maintenance from the system manufacturer are essential to address any issues that may arise.

Benefits of Automatic Egg Collection Systems

Automatic egg collection systems offer numerous benefits to the poultry industry:

- Improved Hygiene: Reducing manual handling of eggs minimizes the risk of contamination and the spread of diseases.

- Increased Efficiency: Automation allows for faster and more consistent egg collection, reducing labor costs and improving productivity.

- Enhanced Egg Quality: By minimizing damage during collection and transportation, automatic systems contribute to higher-quality egg produce.

- Environmental Impact: By reducing the need for manual handling and energy consumption, these systems can help reduce the environmental footprint of poultry farming.

Conclusion

Automatic egg collection systems represent a significant advancement in the poultry industry. By combining advanced technology with practical design, these systems enhance efficiency, sanitation, and overall farm profitability. As the industry continues to evolve, embracing such innovative solutions will be key to remaining competitive and sustainable in the long term.