Automated Disease Prevention Equipment for Chicken Farms in Tanzania: A Game-Changer in Poultry Health Management

Time : 2025-06-30

As the global population continues to grow, so does the demand for poultry products, with Tanzania being one of the leading poultry producers in East Africa. In the quest to ensure high productivity and efficient production, the use of automated disease prevention equipment for chicken farms in Tanzania has become indispensable. This article explores the significance of automated disease prevention equipment, its benefits, and the impact it has on poultry health management.

Introduction

The poultry industry is crucial to the economies of Tanzania, providing employment opportunities, food security, and income for millions. However, maintaining poultry health is challenging, especially in areas prone to diseases like Avian Influenza, Newcastle Disease, and Colibacillosis. Traditional methods of disease prevention may no longer be effective, leading to increased costs and reduced output. This is where automated disease prevention equipment comes into play, revolutionizing poultry health management.

Automated Disease Prevention Equipment: Understanding Its Role

Automated disease prevention equipment for chicken farms in Tanzania consists of sophisticated systems designed to prevent, detect, and manage diseases that threaten poultry health. This includes:

– Air Filtration Systems: These systems help in reducing the spread of airborne diseases by filtering dust and pathogens from the air.

– Climate Control Systems: Maintaining optimal temperature and humidity levels is crucial in preventing the occurrence of diseases in chicken farms.

– Feed Monitoring and Sorting Equipment: Ensuring that the chickens are consuming healthy and uncontaminated feed reduces the risk of food-borne diseases.

– Disease Detection Systems: Early detection of diseases can prevent outbreaks and limit the spread of infectious agents.

Benefits of Automated Disease Prevention Equipment

The integration of automated disease prevention equipment in chicken farms in Tanzania has numerous benefits:

1. Enhanced Disease Control

Automated systems provide better control over diseases compared to traditional methods. By detecting diseases at an early stage, farmers can implement timely interventions, reducing the risk of widespread outbreaks.

2. Improved Productivity

Healthy chickens are more productive. Automated disease prevention equipment minimizes the risk of disease, leading to improved flock health and, consequently, increased production of eggs and meat.

3. Cost-Effective

Although the initial investment in automated equipment might be high, the long-term benefits outweigh the costs. Reduced disease incidence translates to lower treatment and mortality costs, ultimately leading to improved profitability.

4. Increased Consumer Confidence

Chicken products that come from farms implementing advanced disease prevention techniques tend to gain more consumer trust and demand in the market.

Implementing Automated Disease Prevention Equipment in Tanzania

To effectively implement automated disease prevention equipment in chicken farms in Tanzania, the following steps should be considered:

1. Assessing the Farm’s Needs

Before investing in any equipment, it’s essential to assess the farm’s specific requirements based on its size, layout, and current disease challenges.

2. Consulting Experts

Engaging with experts in poultry health management can provide valuable insights into the most suitable equipment for the farm’s needs.

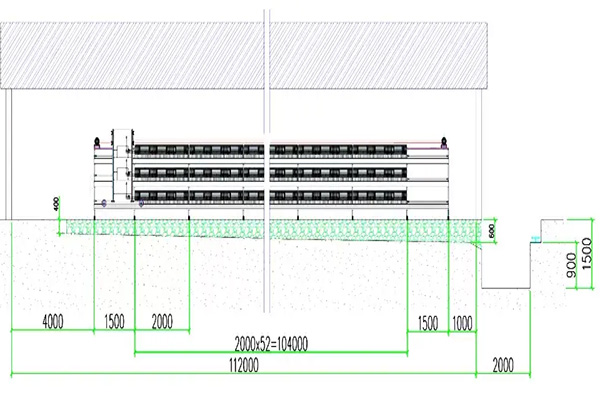

3. Equipment Installation

Once the right equipment has been selected, professional installation by certified technicians is crucial to ensure optimal performance.

4. Training Farm Employees

Proper training of farm staff is essential for maintaining and operating the equipment effectively.

5. Continuous Monitoring

Regular monitoring and maintenance of the equipment are necessary to keep the systems running efficiently and effectively.

Challenges and Solutions

Implementing automated disease prevention equipment in chicken farms in Tanzania comes with certain challenges:

– High Initial Investment Cost: This can be mitigated through government subsidies, loans, or partnerships with private investors.

– Lack of Technical Expertise: Training and education programs can help build a skilled workforce to handle and maintain the equipment.

– Limited Access to Information: Increased awareness and education on the benefits of automated disease prevention can address this issue.

Conclusion

Automated disease prevention equipment has become a cornerstone in poultry health management for chicken farms in Tanzania. By integrating these systems, farmers can achieve better disease control, improved productivity, and increased profitability. As the industry continues to evolve, it is crucial for stakeholders to embrace and promote the use of advanced technologies to ensure the sustainability and success of the poultry sector in Tanzania.

Tags: