Broiler Cage Systems for 70000 Birds: A Comprehensive Guide to High-Volume Production

Time : 2025-07-02

Broiler cage systems are a cornerstone in the commercial poultry industry, particularly for facilities managing large-scale bird populations. With an impressive capacity of 70000 birds, these systems demand a specialized approach to ensure efficient, humane, and cost-effective management. This article delves into the intricacies of broiler cage systems designed for such a large number of birds, providing an in-depth analysis of the key components, operational considerations, and the benefits they offer to poultry farmers.

Understanding Broiler Cage Systems

Broiler cage systems are designed to house and manage broiler chickens (meat-type chickens) in a controlled environment. These systems are characterized by their modular and scalable design, allowing them to accommodate a wide range of bird populations. The design of a 70000-bird broiler cage system is particularly challenging due to the sheer size of the operation. It requires a meticulous balance between animal welfare, production efficiency, and cost management.

Components of Broiler Cage Systems for 70000 Birds

The primary components of a broiler cage system for 70000 birds include:

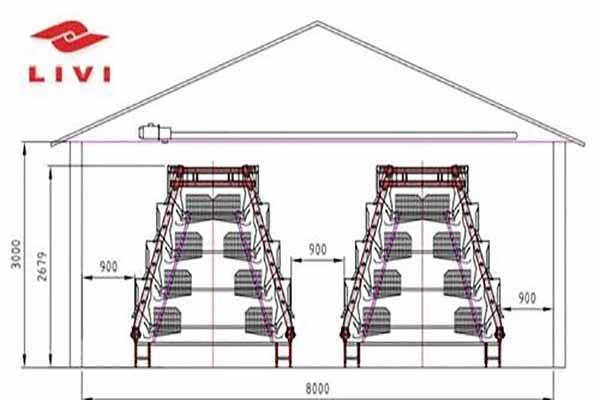

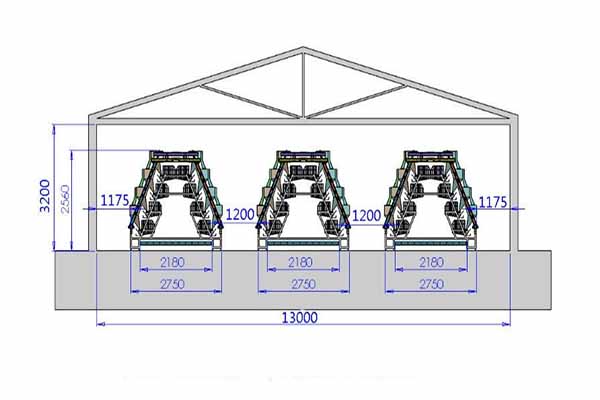

- Cage Construction: High-quality steel is typically used for the construction of broiler cages to ensure durability and safety. The cages are designed to withstand the weight of the birds and the stress of daily operations.

- Feeding and Watering Systems: Automated feeding and watering systems are crucial for maintaining consistent nutrition and hydration throughout the flock. These systems should be designed to serve the entire flock with minimal waste.

- Environmental Control: Efficient ventilation, heating, and cooling systems are essential to create an optimal environment for the birds. This includes managing temperature, humidity, and air quality to ensure the well-being of the chickens.

- Maintenance Equipment: Regular cleaning and maintenance are critical for disease prevention and system performance. The system should be equipped with easy-to-use maintenance tools and equipment.

Operational Considerations for Large-Scale Broiler Cage Systems

Managing a broiler cage system for 70000 birds involves several operational considerations to ensure optimal performance:

Staff Training

Proper training is essential for staff working in a large-scale broiler operation. Workers must be trained in cage management, feed and water system operation, and general biosecurity practices to minimize the risk of disease outbreaks.

Animal Welfare

Animal welfare is a top priority in the broiler industry. Ensuring that the birds are well cared for and living in a healthy environment is crucial for the success of the operation. Regular monitoring and adjustment of the cage systems are essential to meet the needs of the birds.

Efficiency and Cost Management

Running a large-scale broiler operation is a significant investment. To maximize profitability, it is important to monitor and optimize energy consumption, feed conversion rates, and labor costs. Advanced technology and automation can significantly reduce overhead costs and improve overall efficiency.

Benefits of Broiler Cage Systems for 70000 Birds

Implementing a broiler cage system for 70000 birds offers several benefits:

Increased Production Capacity

By utilizing a broiler cage system for such a large number of birds, farmers can significantly increase their production capacity, leading to higher profits and a competitive edge in the market.

Improved Animal Welfare

Well-designed cage systems ensure that birds have ample space, proper ventilation, and easy access to food and water. This promotes the overall well-being of the chickens, leading to better health and quality of meat.

Reduced Disease Outbreaks

Broiler cage systems are designed with biosecurity in mind, minimizing the risk of disease transmission. Regular cleaning, proper ventilation, and controlled access to the facilities help maintain a healthy environment for the birds.

Increased Efficiency and Cost Savings

Automation and advanced technology in broiler cage systems help reduce labor costs and improve efficiency. The ability to monitor and control the environment ensures that resources are used effectively, leading to cost savings.

Conclusion

Broiler cage systems for 70000 birds are complex and multifaceted, requiring careful planning and attention to detail. By prioritizing animal welfare, operational efficiency, and cost management, farmers can harness the benefits of these systems to produce high-quality poultry products. As the demand for meat continues to grow, the rol e of well-designed broiler cage systems in large-scale poultry production will only become more significant.

e of well-designed broiler cage systems in large-scale poultry production will only become more significant.