User Evaluation Reference for Chicken Equipment in Kenya

Time : 2025-07-02

Kenya, a country with a growing poultry industry, has seen a significant increase in the adoption of advanced chicken equipment. As a key player in the poultry sector, understanding the user evaluation of these equipment is crucial for both producers and equipment manufacturers. This article aims to provide a comprehensive reference for evaluating chicken equipment in Kenya, focusing on the needs of the users and the performance of the equipment.

Introduction to Chicken Equipment in Kenya

The poultry industry in Kenya has evolved over the years, with modern chicken equipment playing a pivotal role in improving productivity and reducing labor costs. From feeders and waterers to brooders and ventilation systems, the range of equipment available is vast. However, the selection and evaluation of the right equipment for Kenyan poultry farmers can be challenging.

Key Chicken Equipment in Kenya

- Feeders: Automatic feeders ensure that chickens receive a consistent and controlled amount of feed, reducing waste and improving growth rates.

- Waterers: Access to clean water is crucial for the health and productivity of chickens. Waterers come in various designs, including nipple and cup waterers.

- Brooders: Brooders provide a controlled environment for chicks, keeping them warm and protecting them from the cold.

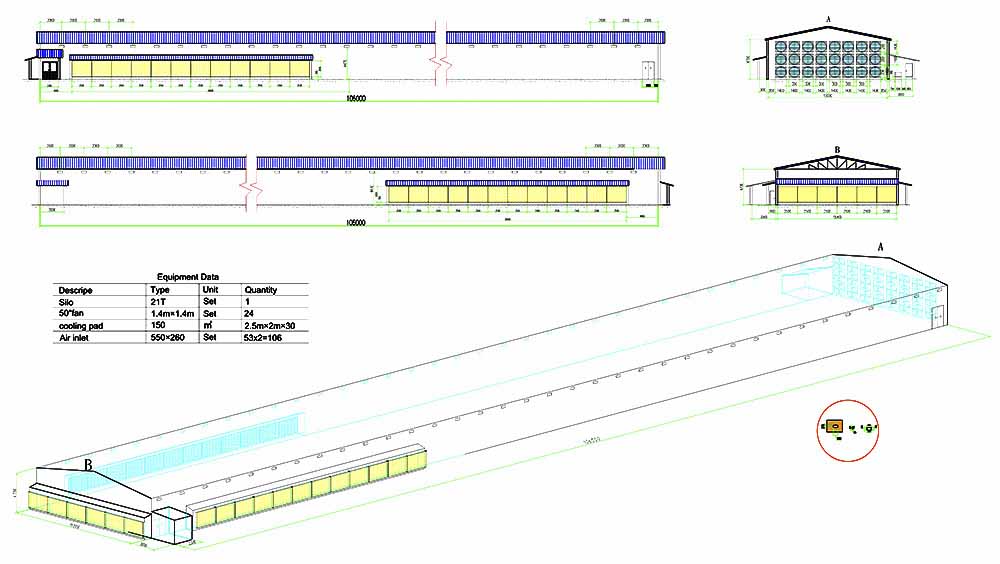

- Ventilation Systems: Proper ventilation is essential for maintaining a healthy atmosphere in the poultry house, reducing the risk of respiratory diseases.

- Lights: Lighting systems are used to regulate the natural light cycle, which is important for the overall health and well-being of chickens.

User Evaluation: Factors to Consider

Evaluating chicken equipment in Kenya requires a multi-faceted approach, considering both the needs of the farmers and the performance of the equipment. The following factors are crucial in the user evaluation process:

1. Reliability and Durability

Reliability is a critical aspect of chicken equipment. Users in Kenya should look for equipment that is robust and can withstand the challenging conditions of the region. Durability ensures that the equipment has a long lifespan, reducing the need for frequent replacements.

2. Efficiency

Efficient equipment can significantly improve the productivity of poultry farms. Users should evaluate the equipment’s ability to perform its intended function effectively, such as feeding, watering, and brooding.

3. User-Friendliness

Chicken equipment should be easy to use and maintain. Users should consider the ease of operation, the availability of user manuals, and the training required to operate the equipment.

4. Cost-Effectiveness

The cost of equipment is a significant factor for most farmers. Users should compare the initial cost of the equipment with its expected lifespan and maintenance costs to determine its cost-effectiveness.

5. after-sales Service

Good after-sales service is essential for the smooth operation of chicken equipment. Users should consider the availability of spare parts, the response time for technical support, and the overall customer service provided by the manufacturer.

Case Studies

Several case studies have been conducted in Kenya to evaluate the performance of chicken equipment. Here are a few examples:

1. Automatic Feeders

A study on automatic feeders found that they reduced feed waste by 15% and improved growth rates by 10%. Users also reported a reduction in labor costs as they no longer needed to manually feed the chickens.

2. Waterers

A comparison of different waterer designs revealed that nipple waterers were more efficient in reducing water spillage compared to cup waterers. Users also preferred nipple waterers for their ease of cleaning and maintenance.

3. Brooders

Brooders with automatic temperature control were found to be more effective in maintaining a consistent temperature for chicks, resulting in better survival rates and reduced mortality.

Conclusion

User evaluation of chicken equipment in Kenya is a vital process for ensuring the success of poultry farms. By considering factors such as reliability, efficiency, user-friendliness, cost-effectiv eness, and after-sales service, farmers can make informed decisions when selecting and purchasing chicken equipment. This article serves as a comprehensive reference for users looking to evaluate and improve their poultry equipment in Kenya.

eness, and after-sales service, farmers can make informed decisions when selecting and purchasing chicken equipment. This article serves as a comprehensive reference for users looking to evaluate and improve their poultry equipment in Kenya.