Implementing an Automated Environmental Control System in Uganda Chicken Farms

Time : 2025-07-02

Uganda, with its rich agricultural heritage, has been witnessing a surge in poultry farming. As the industry grows, the need for efficient and modern farming practices becomes more pronounced. One such practice is the implementation of an automated environmental control system in chicken farms. This article delves into the importance of such systems, their components, and how they can revolutionize the poultry farming landscape in Uganda.

The Need for Automated Environmental Control Systems

Chicken farming, like any other agricultural activity, is heavily dependent on the environment. The success of a chicken farm is largely influenced by factors such as temperature, humidity, air quality, and lighting. Traditional methods of managing these environmental conditions are often time-consuming, labor-intensive, and prone to errors. An automated environmental control system addresses these challenges by providing precise and consistent control over the farm’s environment.

Benefits of Automated Environmental Control Systems

1. Improved Animal Welfare: Chickens are more likely to thrive in a controlled environment. An automated system ensures that the temperature, humidity, and air quality are always within the optimal range, leading to healthier and happier birds.

2. Increased Productivity: By maintaining ideal environmental conditions, the growth rate and productivity of the chickens are significantly improved. This translates to higher egg production and better quality meat.

3. Cost Efficiency: Although the initial investment in an automated system may be high, the long-term savings in terms of energy consumption, labor costs, and healthcare expenses can be substantial.

4. Reduction in Waste: Automated systems can monitor and optimize the use of resources such as water and feed, reducing waste and promoting sustainable farming practices.

Components of an Automated Environmental Control System

An automated environmental control system typically consists of the following components:

Sensors

Sensors play a crucial role in monitoring the farm’s environment. They can detect various parameters such as temperature, humidity, carbon dioxide levels, and ammonia concentration. This data is then used to make real-time adjustments to the farm’s environment.

Control Unit

The control unit is the brain of the system. It processes the data received from the sensors and determines the necessary actions to maintain optimal conditions. This unit can be a standalone device or integrated into a larger farm management system.

Actuators

Actuators are responsible for executing the control unit’s commands. They include fans, heaters, humidifiers, dehumidifiers, and exhaust fans. These devices work together to regulate the farm’s temperature, humidity, and air quality.

User Interface

The user interface allows farmers to monitor and control the system remotely. This can be a smartphone app, a web-based platform, or a dedicated control panel. The interface provides real-time data and allows for easy adjustments to the system settings.

Case Study: Implementing an Automated System in a Uganda Chicken Farm

Let’s take a look at how an automated environmental control system was implemented in a chicken farm in Uganda.

Initial Assessment

The first step was to assess the farm’s current environmental conditions and identify areas that needed improvement. This involved measuring temperature, humidity, and other relevant parameters at different points in the farm.

System Design

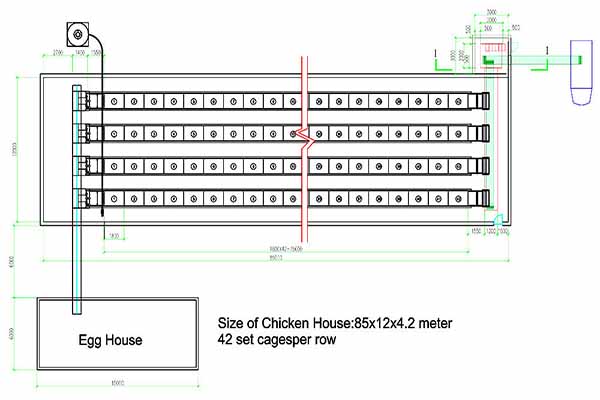

Based on the assessment, a custom system design was developed. This included selecting the appropriate sensors, control unit, actuators, and user interface. The system was designed to be scalable, allowing for future expansion as the farm grows.

Installation and Testing

The automated system was installed in the farm, and all components were tested to ensure they were functioning correctly. This involved checking the accuracy of the sensors, the responsiveness of the actuators, and the ease of use of the user interface.

Monitoring and Adjustment

Once the system was up and running, continuous monitoring and adjustment were carried out. This helped to fine-tune the system settings and ensure that the farm’s environment was always within the optimal range.

Results

The implementation of the automated environmental control system resulted in several notable improvements:

- Consistent temperature and humidity levels throughout the farm

- Significant reduction in energy consumption

- Increased egg production and better quality meat

- Lower healthcare costs due to improved animal welfare

Conclusion

Implementing an automated environmental control system in Uganda chicken farms can bring about significant benefits. By ensuring that the farm’s environment is always within the optimal range, farmers can enjoy improved animal welfare, increased productivity, and cost savings. As the poultry industry continues to grow in Uganda, the adoption of such advanced technologies will be crucial in ensuring its sustainable development.

, , , ,