Automated Breeding Equipment for 10,000 Chickens in Tanzania: A Comprehensive Guide

Time : 2025-07-03

In recent years, the poultry industry in Tanzania has seen significant growth, with a particular focus on commercial chicken farming. To meet the increasing demand for chicken meat and eggs, automated breeding equipment has become a crucial component in modern poultry operations. This article delves into the details of automated breeding equipment designed for a capacity of 10,000 chickens in Tanzania, providing insights into the technology, benefits, and considerations for implementing such a system.

Introduction to Automated Breeding Equipment

Automated breeding equipment refers to a range of technologies and systems that are designed to enhance the efficiency and productivity of poultry farming. These systems typically include incubators, hatchers, feeders, waterers, and environmental control units. By automating various processes, such as egg collection, hatching, feeding, and climate control, farmers can optimize their operations and reduce labor costs.

Design Considerations for 10,000 Chicken Capacity

When designing automated breeding equipment for a capacity of 10,000 chickens in Tanzania, several factors must be taken into account to ensure the system is effective, reliable, and cost-efficient.

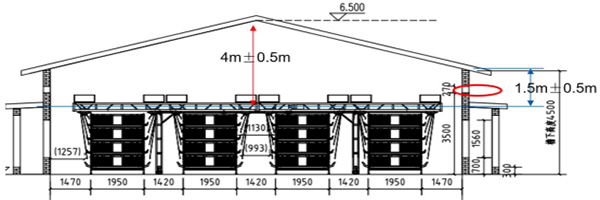

1. Space and Layout

The layout of the poultry house is crucial for the efficient operation of the breeding equipment. The space required will depend on the breed of chicken, the stage of growth, and the specific equipment chosen. For a 10,000 chicken capacity, a well-planned layout should include areas for brooding, growing, and laying hens, as well as space for the automated equipment.

2. Environmental Control

Temperature, humidity, and CO2 levels are critical factors in poultry farming. Automated environmental control systems can monitor and adjust these parameters to create an optimal environment for the chickens. In Tanzania, where temperatures can be extreme, a robust system is essential to maintain the health and productivity of the flock.

3. Feeding and Watering Systems

Automated feeding and watering systems are essential for ensuring that the chickens receive adequate nutrition and hydration. For a 10,000 chicken capacity, these systems should be designed to dispense feed and water at consistent intervals, avoiding waste and ensuring each bird receives the necessary nutrients.

4. Incubation and Hatching Equipment

Incubators and hatchers are key components of automated breeding equipment. They must be capable of maintaining precise temperature and humidity conditions to ensure high hatching rates. In Tanzania, where power supply can be unreliable, backup systems such as generator sets may be necessary to ensure continuous operation.

Benefits of Automated Breeding Equipment

Implementing automated breeding equipment for a 10,000 chicken capacity in Tanzania offers several benefits:

1. Increased Efficiency

Automated systems reduce the need for manual labor, allowing farmers to focus on other aspects of their operation. This can lead to increased productivity and reduced labor costs.

2. Improved Health and Welfare

Automated systems can help maintain optimal environmental conditions, reducing the risk of disease and improving the overall health and welfare of the chickens.

3. Higher Egg and Meat Quality

By providing consistent nutrition and care, automated breeding equipment can lead to higher quality eggs and meat, which can command higher prices in the market.

4. Reduced Waste

Automated systems can minimize feed and water waste, leading to cost savings and a more sustainable operation.

savings and a more sustainable operation.

Challenges and Considerations

While automated breeding equipment offers numerous benefits, there are also challenges and considerations to keep in mind:

1. Initial Investment Costs

The cost of purchasing and installing automated breeding equipment can be significant, particularly for small-scale farmers. However, the long-term cost savings and increased productivity may justify the investment.

2. Technical Expertise

Operating and maintaining automated systems requires specialized knowledge and training. Farmers should consider the availability of technical support and training programs in their region.

3. Energy Supply Reliability

In regions with unreliable power supplies, such as Tanzania, backup systems and alternative energy sources may be necessary to ensure continuous operation of the automated equipment.

Conclusion

Automated breeding equipment for a capacity of 10,000 chickens in Tanzania represents a significant advancement in the poultry industry. By addressing the specific needs of the region and considering factors such as space, environmental control, and feeding systems, farmers can optimize their operations for increased efficiency, productivity, and profitability. While there are challenges to be overcome, the benefits of automated breeding equipment make it a valuable investment for the future of poultry farming in Tanzania.