Automated Transformation Plan for 10,000 Chicken Houses in Tanzania: A Comprehensive Approach

Time : 2025-06-24

The poultry industry in Tanzania is experiencing a remarkable growth, with a substantial number of chicken houses scattered across the country. To keep up with this exponential rise, an automated transformation plan for 10,000 chicken houses is essential to enhance productivity, ensure food safety, and promote sustainability. In this article, we will discuss a detailed and practical approach to transforming these chicken houses into automated, efficient, and high-performance units. This plan aims to integrate advanced technologies and best practices in poultry farming to elevate Tanzania’s poultry industry.

I. Introduction to the Automated Transformation Plan

The automated transformation plan for 10,000 chicken houses in Tanzania focuses on implementing innovative solutions to streamline poultry production. This plan involves integrating automated systems, adopting best management practices, and optimizing the use of resources to achieve sustainable growth. The objective is to increase the overall productivity, enhance animal welfare, and ensure food safety in the poultry sector.

II. Identifying Key Components for Transformation

1. Automation Systems

Automated systems are crucial for transforming chicken houses in Tanzania. The integration of advanced technologies can lead to a significant improvement in the efficiency of poultry production. Some of the key components of automation include:

a. Environmental Control Systems: These systems monitor and regulate the temperature, humidity, and ventilation within the chicken houses, ensuring optimal living conditions for the birds.

b. Feeding Systems: Automated feeding systems can provide precise nutrition to the birds, thereby enhancing their growth and health.

c. Drinking Water Systems: Automatic water supply ensures a constant and clean water supply to the birds, promoting their hydration and overall health.

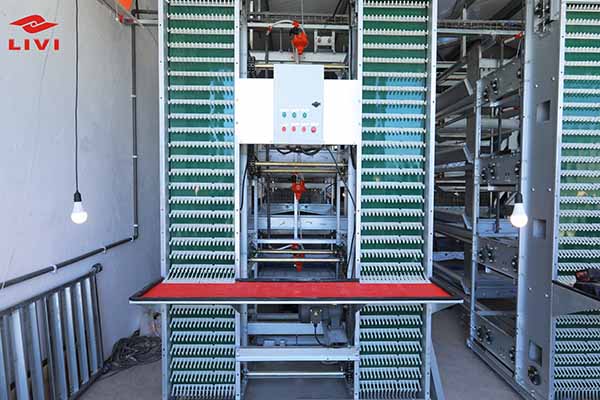

d. Egg Collection Systems: Automated egg collection systems can improve the efficiency of egg collection and reduce labor costs.

2. Biosecurity and Disease Control

Biosecurity is critical in poultry farming to prevent the spread of diseases. An automated transformation plan should include measures to maintain a disease-free environment:

a. Disinfection Systems: Implementing automated disinfection systems can help in preventing the entry of pathogens into the chicken houses.

b. Temperature and Humidity Monitoring: Regular monitoring of temperature and humidity can help in detecting potential disease outbreaks at an early stage.

c. Access Control: Automated systems for controlling access to chicken houses can reduce the risk of introducing pathogens.

3. Energy Efficiency and Sustainability

Energy consumption in poultry farming can be substantial. An automated transformation plan should incorporate energy-efficient practices to reduce costs and environmental impact:

a. Solar Energy: Utilizing solar energy can power the automated systems, thereby reducing electricity consumption and carbon footprint.

b. Energy-Efficient Lighting: Installing LED lighting can help in reducing energy consumption and providing an ideal environment for the birds.

III. Implementation Steps for the Automated Transformation Plan

1. Needs Assessment

Before initiating the transformation, it is essential to conduct a thorough needs assessment. This will involve identifying the current challenges in the poultry industry, evaluating the available resources, and assessing the specific requirements of each chicken house.

2. Technology Selection

Based on the needs assessment, the appropriate automation technologies and equipment should be selected. This will involve considering factors such as budget, scalability, and ease of integration.

3. Training and Capacity Building

A critical aspect of the automated transformation plan is training and capacity building. Farmers, farm managers, and employees need to be equipped with the necessary skills to operate and maintain the automated systems effectively.

4. Project Implementation

The project implementation phase involves the installation and integration of the selected automation systems in the chicken houses. It is essential to ensure that the installation process is carried out meticulously to prevent any operational issues.

5. Monitoring and Evaluation

Continuous monitoring and evaluation of the automated systems and the overall transformation process are essential to identify any potential challenges and address them promptly.

IV. Expected Outcomes of the Automated Transformation Plan

1. Enhanced Productivity: The implementation of automation systems will lead to increased productivity, resulting in higher production output.

2. Improved Animal Welfare: Automated systems will ensure optimal living conditions for the birds, leading to improved animal welfare.

3. Reduced Costs: Energy-efficient practices and reduced labor costs will result in lower operational expenses.

4. Food Safety: The implementation of biosecurity measures will enhance food safety and prevent disease outbreaks.

5. Sustainability: The automated transformation plan will promote sustainability by reducing energy consumption and minimizing the environmental impact.

V. Conclusion

The automated transformation plan for 10,000 chicken houses in Tanzania is a comprehensive approach to elevate the poultry industry. By integrating advanced technologies, adopting best management practices, and focusing on sustainability, this plan aims to enhance productivity, improve animal welfare, and ensure food safety. Implementing this plan will not only benefit the farmers but also contribute to the economic growth and development of Tanzania.