Automatic Poultry Cage System for 80,000 Chickens: A Comprehensive Guide

Time : 2025-06-25

Keeping 80,000 chickens in an efficient and manageable manner requires advanced and specialized equipment. An automatic poultry cage system is the key to achieving this. This article delves into the details of an automatic poultry cage system designed to accommodate 80,000 chickens, discussing its features, benefits, and the technical aspects that make it a game-changer in the poultry industry.

Introduction to Automatic Poultry Cage Systems

Automatic poultry cage systems are designed to provide a controlled environment for raising chickens. These systems ensure optimal conditions for growth, health, and productivity. By automating various processes, these systems reduce labor costs, enhance biosecurity, and contribute to the overall well-being of the birds.

Design and Layout of the System

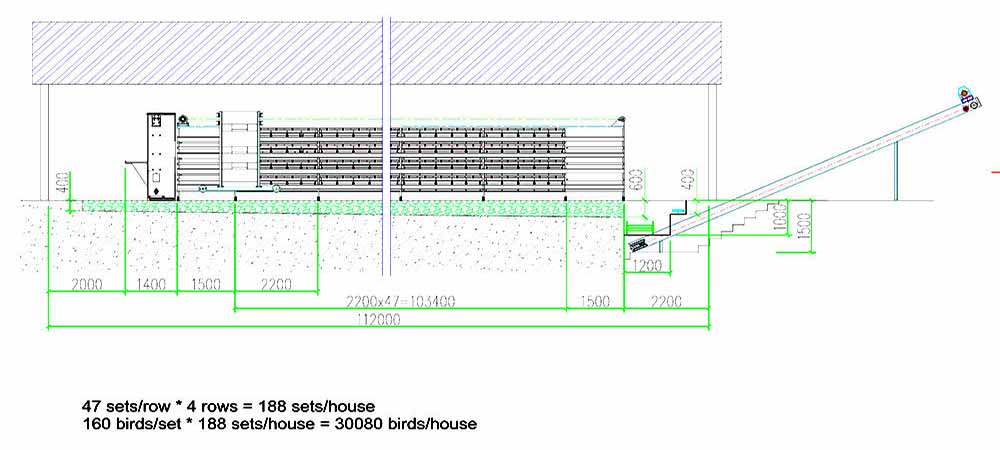

The automatic poultry cage system for 80,000 chickens is designed to maximize space utilization and accommodate the needs of a large flock. Here are some key elements of the system’s design and layout:

- Cage Structure: The system consists of a series of interconnected cages made from high-quality materials. These cages provide a safe and secure environment for the chickens, preventing injuries and diseases.

- Feeding System: An automated feeding system ensures that the chickens receive a balanced diet at regular intervals. This system can be adjusted according to the birds’ age, weight, and nutritional requirements.

- Watering System: The system features an automatic watering system that provides clean, fresh water to the chickens at all times. This system is equipped with filters to prevent the contamination of water.

- Airflow Management: Proper airflow is essential for maintaining a healthy environment. The system includes fans and exhaust systems to regulate the temperature and humidity levels inside the cages.

- Monitoring and Control: The system is equipped with advanced monitoring and control systems to track the chickens’ health, growth, and behavior. This information is crucial for making informed decisions about the flock’s care.

Benefits of the Automatic Poultry Cage System

Automatic Poultry Cage System

Implementing an automatic poultry cage system for 80,000 chickens offers numerous benefits:

- Increased Productivity: The system ensures optimal growth conditions for the chickens, leading to increased productivity and better overall performance.

- Reduced Labor Costs: Automation of various processes reduces the need for manual labor, thereby reducing labor costs.

- Enhanced Biosecurity: The system helps prevent the spread of diseases by controlling the environment and minimizing the risk of contact between chickens.

- Improved Animal Welfare: The system ensures that the chickens are housed in a comfortable, safe, and hygienic environment, contributing to their overall well-being.

- Easy Maintenance: The system is designed for easy maintenance and cleaning, ensuring long-term durability and reliability.

Technical Aspects of the System

Understanding the technical aspects of the automatic poultry cage system for 80,000 chickens is crucial for successful implementation and operation:

- Control Systems: The system relies on advanced control systems to manage various processes, including feeding, watering, and airflow. These systems can be programmed to operate 24/7, ensuring optimal conditions for the chickens.

- Sensors and Monitoring: The system features a variety of sensors that monitor the chickens’ environment, such as temperature, humidity, ammonia levels, and oxygen levels. This information is used to adjust the system settings and ensure optimal conditions for the birds.

- Communication Systems: The system is equipped with communication systems to facilitate data transfer between the various components. This enables real-time monitoring and control from a central location.

- Energy Efficiency: The system is designed to be energy-efficient, reducing operational costs and minimizing the environmental impact.

Implementation and Operation

Implementing an automatic poultry cage system for 80,000 chickens requires careful planning and coordination. Here are some key considerations:

- Site Selection: Choose a suitable location that offers easy access to water, power, and transportation. Ensure that the site is large enough to accommodate the system and allow for expansion.

- Infrastructure: Develop the necessary infrastructure, including the cage structure, feeding, watering, and waste management systems. Ensure that all components are compatible and designed to work together seamlessly.

- Training: Train the staff to operate and maintain the system effectively. This includes understanding the control systems, monitoring and adjusting the system settings, and performing routine maintenance tasks.

- Monitoring: Continuously monitor the system and the chickens’ performance to ensure optimal conditions and identify any issues early on.

Conclusion

An automatic poultry cage system for 80,000 chickens is a sophisticated solution that offers numerous benefits for the poultry industry. By automating various processes, this system ensures optimal growth conditions, reduces labor costs, enhances biosecurity, and contributes to the overall well-being of the chickens. Understanding the design, features, and technical aspects of this system is essential for successful implementation and operation.</ p>

p>