Complete Poultry Cage Solution for 100,000 Birds

Time : 2025-06-29

As the demand for poultry products continues to rise globally, so does the need for efficient and scalable solutions in poultry farming. A complete poultry cage solution for 100,000 birds requires meticulous planning, innovative design, and advanced equipment to ensure optimal conditions for both the animals and the farmer. This article will delve into the essential aspects of creating a comprehensive poultry cage system that caters to the needs of a large-scale operation.

Understanding the Requirements

Before delving into the specifics of the poultry cage solution, it is crucial to understand the fundamental requirements for housing 100,000 birds. These requirements encompass space, ventilation, lighting, feeding, watering, and waste management.

Space Allocation

Adequate space is a cornerstone of any successful poultry farming operation. For 100,000 birds, it is essential to allocate at least 10 square meters per bird. This provides sufficient space for movement and growth, reducing stress and improving overall animal welfare.

Ventilation

Proper ventilation is critical in ensuring that the poultry remains healthy and stress-free. A well-ventilated system should allow for the exchange of fresh air while controlling ammonia levels and dust. This can be achieved through mechanical or natural ventilation systems, depending on the farm’s location and budget.

Lighting

Lighting plays a vital role in poultry farming, as it affects growth rate, egg production, and general well-being. A complete poultry cage solution should incorporate an automated lighting system that simulates natural day-length cycles, promoting optimal performance.

Feeding and Watering

Efficient feeding and watering systems are essential for the smooth operation of a large-scale poultry farm. Modern cage systems typically include automated feeders and waterers that minimize waste and ensure that each bird receives an adequate supply of nutrients and hydration.

Waste Management

Waste management is a crucial aspect of any poultry farming operation. A complete solution should include a system for collecting and disposing of waste in an environmentally friendly manner, while also minimizing odors and health risks.

Designing the Poultry Cage System

Once the requirements have been established, the next step is to design the poultry cage system itself. This involves selecting the appropriate type of cage, determining the layout, and integrating all necessary components.

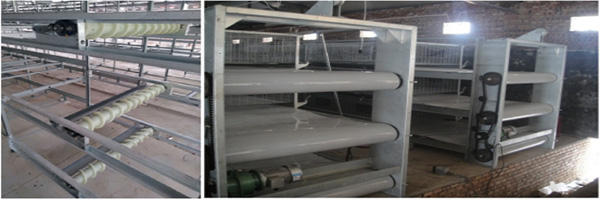

Type of Cage

There are various types of poultry cages available, including single-tier, multi-tier, and free-range systems. For a 100,000-bird operation, a multi-tier system is often the most efficient and cost-effective choice, as it maximizes space utilization and reduces labor requirements.

Layout

The layout of the poultry cage system should be designed to optimize the use of space, ensure easy access for workers, and allow for efficient movement of birds. A common layout for a 100,000-bird operation includes a central walkway with rows of cages on either side.

Components

The components of a complete poultry cage solution include:

– Cages: High-quality, durable cages designed to accommodate the number of birds and the desired stocking density.

– Feeding systems: Automated feeders that dispense food at predetermined intervals.

– Watering systems: Automated drinkers that ensure consistent access to clean water.

– Environmental control systems: Heaters, fans, and humidity controllers to maintain optimal conditions within the cages.

– Waste management systems: Solid manure handling and slurry storage systems.

– Lighting and ventilation systems: Automated systems to control day-length cycles and air exchange.

Integration and Automation

To create a truly comprehensive poultry cage solution, integration and automation are key. By integrating all the components of the system, farmers can achieve seamless operation, minimize waste, and improve overall efficiency.

Integration

Integration involves connecting the various components of the poultry cage system, such as feeding, watering, lighting, and waste management, to a central control unit. This allows for the monitoring and adjustment of all aspects of the system from a single location.

Automation

Automation is the process of automating tasks that are typically performed manually. In a poultry farming operation, automation can include:

– Automated feeding and watering systems.

– Automated environmental control systems.

– Automated waste management systems.

– Automated health monitoring and data collection systems.

By implementing an integrated and automated poultry cage solution, farmers can achieve the following benefits:

– Reduced labor costs.

– Improved efficiency.

– Increased productivity.

– Enhanced animal welfare.

– Better resource utilization.

Conclusion

Creating a complete poultry cage solution for 100,000 birds requires careful planning, innovative design, and advanced equipment. By focusing on space allocation, ventilation, lighting, feeding, watering, and waste management, and by integrating and automating the system, farmers can create a successful and sustainable operation.