Efficiency Comparison of Egg Collectors in Tanzania

Time : 2025-07-02

In the poultry industry, egg collection is a critical process that directly impacts the overall efficiency and profitability of egg production. Tanzania, like many African countries, has a growing poultry sector that requires efficient egg collection systems. This article aims to provide a comprehensive comparison of various egg collectors used in Tanzania, focusing on their efficiency, practicality, and impact on the industry. By delving into the technical aspects and real-world applications, we aim to offer valuable insights for farmers and industry professionals.

Introduction to Egg Collectors

Egg collectors are designed to gather eggs from poultry houses and transport them to storage or processing areas. They come in various types, each with unique features and benefits. The selection of an egg collector depends on factors such as the scale of operation, budget, and specific requirements of the farm.

Manual Egg Collectors

Manual egg collectors are the simplest and most common types used in small-scale poultry farming. These collectors involve the use of baskets or boxes that farmers manually carry from the poultry house to the collection area. While they are cost-effective and easy to maintain, they are labor-intensive and time-consuming, which can lead to inefficiencies in larger operations.

Plastic Egg Trays

Plastic egg trays are another popular manual method. These trays are placed in the poultry house and collected at regular intervals. They are suitable for small to medium-sized flocks and are easy to clean and disinfect. However, they require a considerable amount of manual labor and do not cater to the needs of large-scale farms.

Automatic Egg Collectors

Automatic egg collectors are designed to reduce labor requirements and increase efficiency in egg collection. They are suitable for larger farms and can be categorized into two main types: belt conveyors and robotic systems.

Belt Conveyors

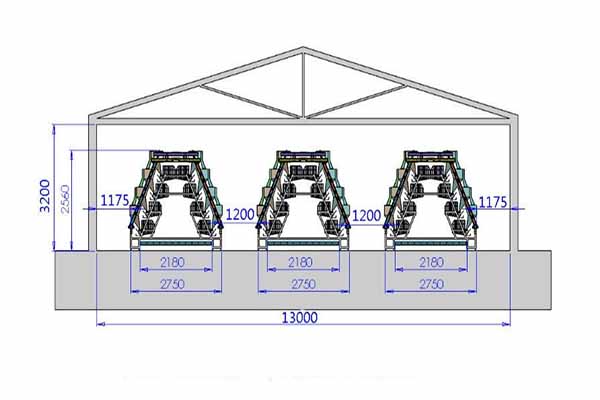

Belt conveyors are the most widely used automatic egg collectors in Tanzania. They consist of a conveyor belt that moves through the poultry house, collecting eggs as they fall onto it. The eggs are then transported to the collection area. Belt conveyors are efficient, easy to install, and maintain, but they may require regular cleaning to prevent the buildup of dirt and debris.

Robotic Systems

Robotic egg collectors are a more advanced option, utilizing automated systems to collect eggs. These systems are capable of navigating around obstacles and can be programmed to collect eggs at specific intervals. While more expensive and complex to install, robotic systems offer higher efficiency and can reduce labor costs significantly.

Efficiency Comparison

When comparing the efficiency of egg collectors in Tanzania, several factors must be considered, including labor requirements, egg collection rates, and maintenance costs.

Labor Requirements

Manual egg collectors require a significant amount of labor, which can be a burden for farmers, especially those with large flocks. Automatic collectors, on the other hand, reduce labor requirements, allowing farmers to focus on other aspects of poultry farming.

Plastic Egg Trays vs. Belt Conveyors

While plastic egg trays are easier to handle and clean, they are less efficient than belt conveyors. The trays may get misplaced or damaged, leading to lost eggs and increased manual labor. Belt conveyors, while requiring more initial investment, offer a more reliable and efficient egg collection process.

Manual vs. Automatic Systems

Automatic egg collectors, such as belt conveyors and robotic systems, are generally more efficient than manual methods. They reduce the risk of eggs being lost or damaged during collection and can be integrated into larger automation systems for further efficiency gains.

Egg Collection Rates

The efficiency of an egg collector is also measured by its egg collection rate. Automatic collectors, particularly robotic systems, can achieve higher collection rates due to their continuous operation and reduced risk of human error.

Belt Conveyors vs. Robotic Systems

Belt conveyors are generally more cost-effective than robotic systems but may have lower egg collection rates. Robotic systems can operate 24/7 and are not subject to the same limitations as manual labor, making them more efficient in terms of egg collection.

Maintenance Costs

Maintenance costs are an essential factor to consider when comparing egg collectors. Manual systems generally have lower maintenance costs since they require minimal mechanical components. Automatic collectors, particularly robotic systems, may have higher maintenance costs due to their complex mechanisms and need for specialized parts.

Belt Conveyors vs. Manual Systems

Belt conveyors typically have lower maintenance costs compared to manual systems due to their simpler design. However, they may require regular cleaning and adjustments to ensure smooth operation.

Conclusion

In conclusion, the efficiency of egg collectors in Tanzania varies significantly depending on the type of system used. While manual collectors, such as plastic egg trays, are cost-effective and easy to use, they are inefficient and impractical for large-scale operations. Automatic collectors, such as belt conveyors and robotic systems, offer higher efficiency, reduced labor requirements, and better egg collection rates. The choice of an egg collector should be based on the specific needs of the farm, budget constraints, and the desired level of efficiency.

As the poultry industry continues to grow in Tanzania, investing in efficient egg collectors will be crucial for farmers and industry professionals to maximize their profitability and ensure the sustainab ility of their operations.

ility of their operations.