Optimizing Broiler Cage H-Type Factory Operations: A Comprehensive Guide

Time : 2025-06-25

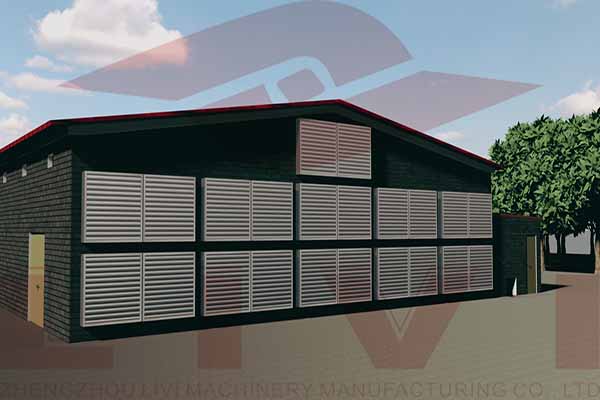

Broiler cage H-type factories play a crucial role in the modern poultry industry, providing efficient and hygienic environments for raising broiler chickens. This article delves into the intricacies of H-type broiler cage factories, offering insights into their design, operation, and the latest advancements in the field. By understanding the key aspects of these factories, poultry farmers and industry professionals can enhance productivity and ensure the well-being of their broilers.

Understanding Broiler Cages

Broiler cages are designed to house broiler chickens, providing a controlled environment that promotes growth and minimizes the risk of disease. The H-type broiler cage is a popular choice due to its versatility and efficiency. These cages are characterized by their unique H-shaped design, which allows for optimal space utilization and ease of management.

Design Principles of H-Type Broiler Cages

The design of H-type broiler cages is based on several key principles:

- Space Utilization: The H-shape maximizes the floor area available for each bird, ensuring ample space for movement and growth.

- Hygiene: The elevated design of the H-type cage helps in maintaining a clean environment by preventing the accumulation of droppings and waste.

- Easy Management: The modular design of H-type cages allows for easy cleaning, maintenance, and reconfiguration as needed.

Key Components of H-Type Broiler Cages

Understanding the components of H-type broiler cages is essential for their proper installation and maintenance. The following are some of the primary components:

1. Frame Structure

The frame structure of an H-type broiler cage is typically made of steel, providing durability and stability. It supports the entire cage system and ensures that it can withstand the weight of the chickens and the environmental conditions.

2. Mesh Panels

The mesh panels are the primary component that allows air circulation and prevents the chickens from escaping. These panels are designed to be easy to clean and resistant to corrosion.

3. Feeding System

The feeding system is an integral part of the H-type broiler cage. It ensures that the chickens have access to feed at all times, with systems like automated feeders or gravity-based feeders being commonly used.

4. Watering System

Access to clean water is crucial for the health of broiler chickens. The watering system in H-type cages is designed to provide continuous access to fresh water, with options like nipple drinkers or cup drinkers available.

5. Ventilation

Proper ventilation is essential for maintaining a healthy environment in the broiler cage. The ventilation system is designed to provide adequate air exchange, controlling temperature and humidity levels.

Factory Setup and Operation

Setting up and operating an H-type broiler cage factory requ ires careful planning and attention to detail. The following steps outline the key aspects of the process:

ires careful planning and attention to detail. The following steps outline the key aspects of the process:

1. Site Selection

The selection of a suitable site is crucial for the success of a broiler cage factory. Factors to consider include proximity to feed suppliers, water sources, and transportation routes.

2. Design and Planning

The design of the factory should be based on the specific requirements of the broiler chickens and the expected production capacity. It should incorporate all necessary components, including broiler cages, feed storage, and waste management systems.

3. Installation and Setup

The installation of the H-type broiler cages should be carried out by professionals who are familiar with th e equipment. It is important to ensure that all components are properly aligned and functioning correctly.

e equipment. It is important to ensure that all components are properly aligned and functioning correctly.

4. Training and Maintenance

Employees should receive proper training on the operation and maintenance of the H-type broiler cages. Regular maintenance is essential to prevent breakdowns and ensure the health and well-being of the chickens.

Advancements in H-Type Broiler Cages

The poultry industry is continuously evolving, and advancements in H-type broiler cage technology are being made to enhance efficiency and sustainability. Some of the latest developments include:

1. Automated Systems

Automated feeding, watering, and ventilation systems are becoming increasingly popular in H-type broiler cage factories. These systems reduce labor costs and improve accuracy, leading to better overall productivity.

2. Environmentally Friendly Materials

The use of environmentally friendly materials in the construction of H-type broiler cages is gaining traction. These materials are not only sustainable but also contribute to a reduction in the carbon footprint of the factory.

3. Smart Monitoring Systems

Smart monitoring systems that use IoT technology are being integrated into H-type broiler cage factories. These systems provide real-time data on the health and performance of the chickens, allowing for timely interventions.

Conclusion

H-type broiler cage factories are a cornerstone of the modern poultry industry. By understanding the design principles, key components, and operational aspects of these factories, poultry farmers and industry professionals can optimize their operations and ensure the health and productivity of their broiler chickens. As technology continues to advance, the future of H-type broiler cage factories looks promising, with innovations that promise to further enhance efficiency and sustainability.