Optimizing Chicken Farm Efficiency in Uganda with Automated Manure Cleaners: Which System is Best?

Time : 2025-07-03

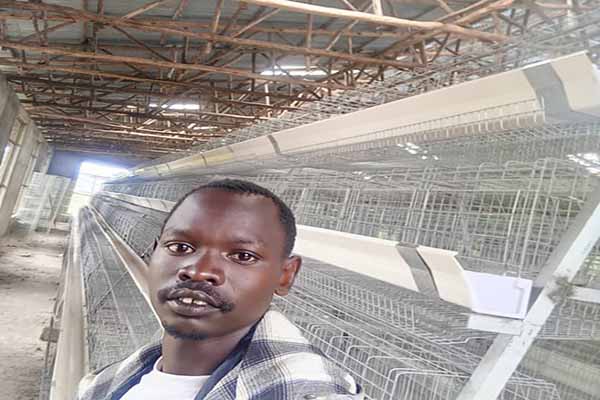

Uganda, a country known for its rich agricultural heritage, is increasingly looking towards modernizing its poultry sector. One of the key areas of innovation is the adoption of automated manure cleaners in chicken farms. This article delves into the importance of automated manure cleaning systems in Uganda, their benefits, and a comparative analysis of the most effective systems available to enhance farm efficiency.

The Need for Automated Manure Cleaners in Uganda’s Chicken Farms

Uganda’s chicken farming industry has seen significant growth over the years. However, with this growth comes the need for efficient waste management systems. Traditional methods of manure removal are not only labor-intensive but also pose health risks to both workers and the environment. Automated manure cleaners have emerged as a solution to these challenges.

Health and Environmental Benefits

Manual manure removal can lead to the spread of diseases, not only among chickens but also among farm workers. Automated systems, on the other hand, minimize human contact with waste, reducing the risk of disease transmission. Moreover, these systems help in reducing the environmental impact by effectively managing waste and promoting sustainable farming practices.

Types of Automated Manure Cleaning Systems

Several automated manure cleaning systems are available for chicken farms in U ganda. Each system has its unique features and advantages. Let’s take a closer look at some of the most popular ones:

ganda. Each system has its unique features and advantages. Let’s take a closer look at some of the most popular ones:

1. Solids Separation System

The solids separation system is designed to separate solid waste from liquid waste. It uses a combination of screens and conveyors to remove solid particles from the manure, which can then be composted or used as organic fertilizer. This system is ideal for large-scale chicken farms with high manure production.

2. Scrape System

The scrape system involves the use of a rotating blade or chain to scrape manure from the floor of the chicken house. This system is efficient in removing manure and can be equipped with conveyors to transport the waste to a storage area. It is suitable for farms with a moderate to high manure production rate.

3. Flush System

The flush system uses water to wash manure from the floor of the chicken house. The waste is then transported to a storage area using conveyors or a flushing system. This system is ideal for farms with a low to moderate manure production rate and is more labor-intensive than the scrape system.

Comparative Analysis: Which System is Best for Uganda’s Chicken Farms?

Selecting the most suitable automated manure cleaning system for a chicken farm in Uganda depends on various factors, including the size of the farm, the volume of manure produced, and the available budget. Let’s compare the three systems mentioned above based on these factors:

1. Solids Separation System

Pros:

- Effective in managing both solid and liquid waste

- Can be used for large-scale chicken farms with high manure production

Cons:

- High initial investment cost

- Complex installation and maintenance requirements

2. Scrape System

Pros:

- Efficient in removing manure from the floor

- Suitable for farms with a moderate to high manure production rate

Cons:

- May require more frequent maintenance than flush systems

- Not as effective in managing liquid waste

3. Flush System

Pros:

- Lower initial investment cost compared to solids separation systems

- Relatively simple to install and maintain

Cons:

- More labor-intensive than scrape systems

- Not suitable for farms with a high manure production rate

Conclusion

Selecting the best automated manure cleaning system for a chicken farm in Uganda requires careful consideration of various factors. While the solids separation system is the most efficient and effective, it comes with a high initial investment cost. For smaller farms with a moderate manure production rate, the scrape system may be a more practical choice. Ultimately, the best system will depend on the specific needs and budget of the farm.