Optimizing Commercial Farm Layout with 45,000 Broiler Chicken Cages

Time : 2025-07-03

In the modern poultry industry, the efficient management of broiler chicken farming operations is paramount. With the demand for commercial broiler chicken production on the rise, the installation of a robust and scalable system is essential. This article delves into the design and implementation of a 45,000 broiler chicken cage system for commercial farms, focusing on the key aspects of poultry equipment and farm layout optimization.

Understanding the Broiler Chicken Cage System

A broiler chicken cage system is a structured environment designed to house broiler chickens in a commercial setting. These cages provide a controlled environment that supports the health and growth of the chickens, while also ensuring efficient production and ease of management. For a farm housing 45,000 broiler chickens, the design of the cage system is critical to the overall success of the operation.

Material and Construction

The material used for constructing broiler chicken cages is a crucial factor. High-quality steel is commonly used due to its durability and resistance to corrosion. The design should incorporate a sturdy frame that can withstand the weight of the chickens and the stress of daily handling. The cage floor should be made of a non-slip material to prevent injuries to the chickens and to ensure easy cleaning.

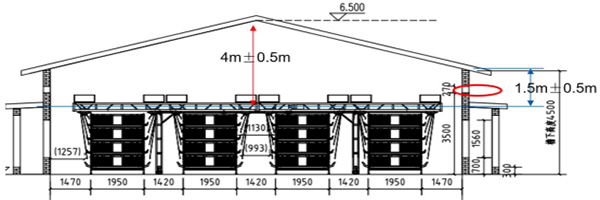

Layout Considerations

The layout of the broiler chicken cages plays a significant role in the farm’s efficiency. Here are some key considerations for a 45,000 broiler chicken cage system:

Airflow and Temperature Control

Proper airflow is essential for maintaining a healthy environment for the chickens. The cage system should be designed to allow for adequate ventilation, with fans and air inlets strategically placed to ensure uniform temperature distribution. Climate control systems may also be integrated to manage temperature fluctuations, especially in regions with extreme weather conditions.

Lighting and Sanitation

Lighting is another critical component of the broiler chicken cage system. It should mimic natural daylight to promote growth and health. Automated lighting systems can be used to control the intensity and duration of light exposure. Additionally, easy access for cleaning and disinfection is vital to prevent disease outbreaks and maintain a hygienic environment.

Space Allocation

Each broiler chicken requires a certain amount of space to move around comfortably. The cage size and the number of chickens per cage should be determined based on industry standards and the specific breed being raised. Ensuring ample space can reduce stress and improve the quality of the meat produced.

Automated Feeding and Watering Systems

Automated feeding and watering systems are integral to a large-scale broiler chicken operation. These systems ensure consistent access to food and water, which is crucial for the chickens’ growth and development. The systems should be designed to minimize waste and be easy to maintain.

Monitoring and Management

With 45,000 broiler chickens, manual monitoring is impractical. Implementing a comprehensive monitoring system allows for real-time data collection on the chickens’ health, weight, and behavior. This data can be used to make informed decisions and optimize the farming process.

Conclusion

Designing and implementing a 45,000 broiler chicken cage system for commercial farms requires careful planning and a deep understanding of poultry equipment. By focusing on material quality, layout optimization, automated systems, and effective monitoring, a commercial farm can achieve high levels of efficiency and productivity. The successful integration of these elements will not only enhance the farm’s profitability but also contribute to the overall sustainability of the poultry industry.