Recommended Automatic Manure Cleaning Equipment for Large Chicken Farms in Kenya

Time : 2025-07-01

In the dynamic and rapidly growing poultry industry of Kenya, large-scale chicken farms are increasingly seeking efficient and reliable solutions for manure management. Automatic manure cleaning equipment has become a crucial investment for these farms to maintain hygiene, improve biosecurity, and optimize operational efficiency. This article delves into the recommended automatic manure cleaning equipment for large chicken farms in Kenya, ensuring that farmers make informed decisions for their operations.

Understanding the Challenges of Manure Management in Large Chicken Farms

Large chicken farms generate a significant amount of manure daily, which poses several challenges if not managed properly. These challenges include the risk of disease outbreaks, environmental pollution, and the need for labor-intensive cleaning operations. To address these issues, investing in high-quality automatic manure cleaning equipment is essential.

Health and Biosecurity Concerns

The accumulation of manure can lead to the spread of diseases among the chickens. The organic matter in manure serves as a breeding ground for pathogens such as Salmonella and E. coli. Automatic manure cleaning equipment helps in promptly removing manure, thus reducing the risk of disease transmission within the flock.

Environmental Impact

Manure, if left unmanaged, can contribute to water and soil pollution. It contains nutrients and pathogens that can seep into the groundwater or be carried by runoff into nearby water bodies. Efficient manure removal ensures that these pollutants are controlled, minimizing environmental impact.

Operational Efficiency

Manually cleaning large chicken farms is time-consuming and labor-intensive. Investing in automatic manure cleaning equipment can reduce the workload on farm staff, allowing them to focus on other critical farm operations. This, in turn, enhances overall farm efficiency.

Recommended Automatic Manure Cleaning Equipment for Large Chicken Farms in Kenya

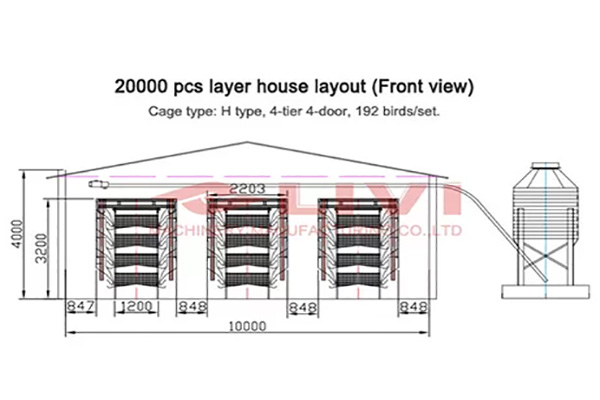

When selecting automatic manure cleaning equipment for large chicken farms in Kenya, it is crucial to consider factors such as the layout of the farm, the size of the chicken houses, and the specific requirements of the operation. Here are some recommended pieces of equipment:

Manure Scrape Systems

Manure scrape systems are designed to remove solid waste from chicken houses, ensuring a clean and hygienic environment. These systems can be installed on the floors of chicken houses or suspended above the floors. They work by using a series of metal blades or chains that scrape the manure into collection bins.

Benefits:

- Reduces labor requirements

- Improves biosecurity by minimizing contact with manure

- Can be integrated with other waste management systems

Manure Pit Cleaners

For chicken houses with manure pits, manure pit cleaners are a vital piece of equipment. These machines automatically remove manure from the pits, preventing the build-up of harmful gases and ensuring that the pits do not overflow.

Benefits:

- Safe and efficient manure removal

- Prevents pit overflow and gas buildup

- Reduces the risk of accidents and injuries

Automatic Solid Separators

Automatic solid separators are used to remove solid waste from liquid manure. This allows for the separation of nutrients and organic matter, which can be used as fertilizers or for energy production.

Benefits:

- Improves manure treatment efficiency

- Reduces sludge disposal costs

- Enhances biosecurity by minimizing solid waste exposure

Manure Composting Machines

For on-farm composting, manure composting machines are essential. These machines turn manure into compost, a valuable organic material that can be used for soil enrichment.

Benefits:

- Reduces the amount of manure that needs to be disposed of

- Improves soil fertility

- Contributes to a sustainable farming practice

Considerations for Implementation

Implementing automatic manure cleaning equipment in large chicken farms requires careful planning and consideration. Here are some key points to keep in mind:

Site Assessment

Before selecting and installing the equipment, a thorough site assessment should be conducted. This involves evaluating the farm layout, existing infrastructure, and environmental factors.

Regulatory Compliance

It is important to ensure that the chosen equipment complies with local regulations regarding manure management and disposal.

Training and Maintenance

The farm staff should be properly trained on the operation and maintenance of the equipment to ensure optimal performance and longevity.

Total Cost of Ownership

While the initial investment in automatic manure cleaning equipment can be substantial, the long-term cost savings in labor, disease prevention, and environmental compliance make it a worthwhile investment for large chicken farms in Kenya.

Conclusion

Investing in recommended automatic manure cleaning equipment for large chicken farms in Kenya is a strategic move to enhance biosecurity, improve environmental stewardship, and optimize operational efficiency. By carefully selecting the right equipment and adhering to proper implementation practices, farmers can crea te a sustainable and profitable poultry operation.

te a sustainable and profitable poultry operation.