Revolutionizing poultry farming: Automatic sorting equipment at Uganda’s large chicken farm

Time : 2025-06-25

In the heart of Uganda, a revolution is taking place in the poultry industry with the introduction of advanced automatic sorting equipment at a large chicken farm. This innovation is not only improving efficiency but also ensuring better health and quality for the chickens, making it a game-changer for farmers and consumers alike.

Introduction to Uganda’s poultry industry

The poultry industry in Uganda has seen significant growth in recent years, thanks to the government’s initiatives to support agriculture and promote rural development. The sector has become a major contributor to the country’s economy, providing employment and a source of livelihood for many.

However, as the industry expands, there is an increasing need for efficient management and modern technologies to maintain high-quality standards. One such technology is automatic sorting equipment, which is now being implemented at a large chicken farm in Uganda.

Understanding the benefits of automatic sorting equipment

Automatic sorting equipment is designed to streamline the sorting process in poultry farms. This advanced technology uses sensors, cameras, and software to accurately identify and separate chickens based on their weight, size, color, and other physical characteristics.

Here are some of the key benefits of implementing automatic sorting equipment in poultry farms:

- Improved efficiency: The manual sorting process can be time-consuming and labor-intensive. Automatic sorting equipment can handle thousands of chickens in a short period, reducing labor costs and increasing productivity.

- Enhanced quality control: By ensuring that chickens are sorted based on their physical characteristics, the equipment helps maintain a high standard of quality. This, in turn, improves the value of the end products and increases consumer satisfaction.

- Reduced stress on chickens: Manual sorting can be stressful for the birds. Automatic sorting minimizes the physical handling required, leading to healthier and less stressed chickens.

- Data-driven decision-making: The equipment generates valuable data that can be used to make informed decisions regarding nutrition, health, and other farm management practices.

Implementing automatic sorting equipment at Uganda’s large chicken farm

At the large chicken farm in Uganda, the implementation of automatic sorting equipment has been a significant milestone. The farm’s management has invested in the latest technology to improve its operations and ensure sustainable growth.

Here is an overview of the implementation process:

1. Assessment and planning

Before purchasing and installing the equipment, the farm conducted a thorough assessment of its needs and budget. They engaged with experts to ensure that the chosen technology would meet their specific requirements.

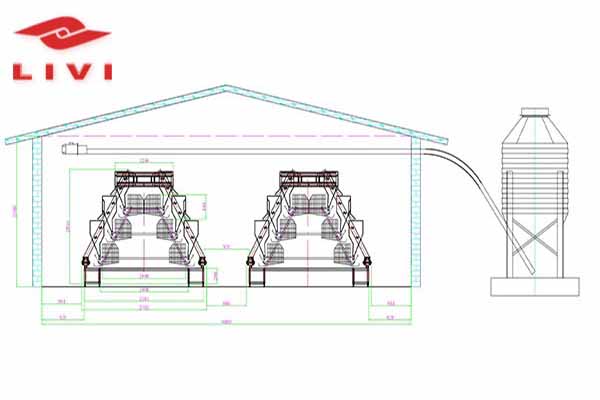

2. Purchasing and installation

The farm purchased state-of-the-art automatic sorting equipment that was specifically designed for large-scale poultry operations. The equipment was installed with the help of trained technicians to ensure proper alignment and functionality.

3. Training and operation

Staff members were trained on how to operate the new equipment, including routine maintenance and troubleshooting. The training focused on safety protocols and best practices to ensure efficient and safe operation.

4. Integration with existing systems

The automatic sorting equipment was integrated with the farm’s existing management systems, allowing for real-time data collection and analysis. This ensures that the farm can make informed decisions and monitor the health and performance of its chickens.

Challenges and future prospects

While the implementation of automatic sorting equipment has been successful, the farm has faced some challenges. One of the main challenges has been adapting to the new technology, as it requires a change in the way the staff operates. However, with proper training and support, the staff has quickly become proficient in using the new equipment.

The future prospects for the use of automatic sorting equipment in Uganda’s poultry industry are promising. As the industry continues to grow, more farms are expected to adopt this technology to stay competitive and maintain high-quality standards.

Here are some potential future developments:

- Integration with IoT technology: By integrating the sorting equipment with the Internet of Things (IoT), the farm can gather even more data and optimize its operations further.

- Development of custom sorting algorithms: As the technology evolves, farmers can develop custom sorting algorithms to cater to their specific needs, such as identifying and addressing genetic diseases in their flocks.

- Increased adoption across the industry: With more farms implementing automatic sorting equipment, the poultry industry as a whole can benefit from increased efficiency, better quality, and improved health of the chickens.

Conclusion

The introduction of automatic sorting equipment at Uganda’s large chicken farm marks a significant step towards modernizing the poultry industry. This innovative technology not only improves efficiency and quality but also reduces stress on chickens and enhances data-driven decision-making. As the industry continues to evolve, we can expect more farms to adopt this technology, paving the way for a sustainable and profitable future for poultry farming in Uganda.

expect more farms to adopt this technology, paving the way for a sustainable and profitable future for poultry farming in Uganda.