Tanzania’s 10,000 Chicken Automatic Egg Collection Machine Revolutionizes Poultry Farming

Time : 2025-07-03

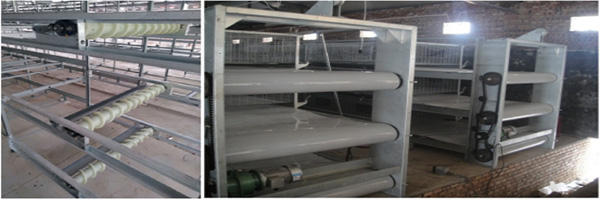

With the rapid growth of the poultry industry in Tanzania, the need for efficient and automated solutions has become paramount. The introduction of the 10,000 chicken automatic egg collection machine marks a significant step forward in the region’s poultry farming practices. This article delves into the details of this innovative machine, exploring its features, benefits, and the impact it has on Tanzania’s poultry industry.

Introduction to the 10,000 Chicken Automatic Egg Collection Machine

The 10,000 chicken automatic egg collection machine is a cutting-edge technology designed to cater to the needs of large-scale poultry farms in Tanzania. It is capable of handling up to 10,000 laying hens, significantly improving the efficiency of egg collection and reducing labor costs.

Key Features of the Automatic Egg Collection Machine

1. Automated Egg Collection: The machine is equipped with advanced sensors and conveyors that automatically collect eggs from the nests. This eliminates the need for manual collection, ensuring a cleaner and more hygienic environment.

2. Real-time Monitoring: The system includes a built-in monitoring system that provides real-time data on egg production, nest temperatures, and other critical parameters. This allows farmers to make informed decisions and optimize their farming practices.

3. Adjustable Nesting Boxes: The machine is designed with adjustable nesting boxes, which can accommodate different hen breeds and sizes. This flexibility ensures optimal comfort for the birds and increased egg production.

4. Intelligent Nest Management: The system utilizes intelligent algorithms to manage nesting behavior, reducing the risk of egg breakage and ensuring a steady supply of eggs.

Benefits of the Automatic Egg Collection Machine

1. Increased Efficiency: The machine automates the egg collection process, drastically reducing the time and labor required for manual collection. This allows farmers to focus on other aspects of poultry farming, such as feed management and disease prevention.

2. Improved Egg Quality: By minimizing manual handling, the machine ensures that eggs are collected in a clean and controlled environment, reducing the risk of contamination and maintaining higher egg quality.

3. Cost Reduction: The initial investment in the machine may seem significant, but the long-term cost savings are substantial. Reduced labor costs, improv ed egg quality, and increased production efficiency all contribute to a more profitab

ed egg quality, and increased production efficiency all contribute to a more profitab le operation.

le operation.

Impact on Tanzania’s Poultry Industry

The introduction of the 10,000 chicken automatic egg collection machine has had a profound impact on Tanzania’s poultry industry. Here are some key points:

1. Increased Production Capacity: The machine allows large-scale poultry farms to increase their production capacity, meeting the growing demand for eggs in the domestic and international markets.

2. Job Creation: As the industry becomes more automated, there is an opportunity for the creation of new jobs in areas such as machine maintenance and technical support.

3. Technological Advancement: The adoption of such advanced machinery promotes technological advancement within the poultry industry, encouraging further innovation and investment.

Conclusion

The 10,000 chicken automatic egg collection machine is a game-changer for Tanzania’s poultry industry. By improving efficiency, reducing costs, and enhancing egg quality, this innovative technology is paving the way for a brighter future in poultry farming. As the industry continues to evolve, it is essential for farmers to embrace such advancements to stay competitive and meet the ever-growing demand for eggs.