The Cost of Automation Equipment for a 20,000 Chicken Farm in Kenya

Time : 2025-07-01

The poultry industry in Kenya has been experiencing significant growth, with more farmers looking to increase their production capacity and efficiency. One way to achieve this is through automation. A 20,000 chicken farm requires advanced automation equipment to manage the various aspects of the farming process. This article delves into the cost implications of automating such a farm, providing valuable insights for both potential investors and existing farmers.

Understanding Automation in Chicken Farming

Automation in chicken farming refers to the use of machinery and technology to manage tasks that were traditionally done manually. This includes feeding, water supply, climate control, egg collection, and waste management. The goal is to improve efficiency, reduce labor costs, and enhance the overall welfare of the chickens.

Key Components of Automation Equipment

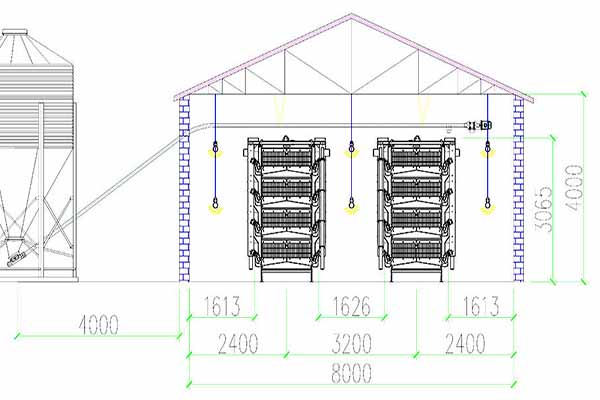

For a 20,000 chicken farm, the following equipment is typically required:

- Feeding Systems: Automated feeding systems ensure that chickens receive a consistent and balanced diet. These systems can be designed to deliver feed at specific intervals or based on the chickens’ consumption patterns.

- Water Supply: Automated water systems ensure a continuous supply of clean water to the chickens. They can be equipped with filtration systems to maintain water quality.

- Climate Control: Automated climate control systems maintain optimal temperatures and humidity levels within the farm. This is crucial for the health and growth of the chickens.

- Egg Collection: Automated egg collection systems minimize the risk of eggs being broken or damaged during collection. They often include conveyors and separators to streamline the process.

- Waste Management: Automated waste management systems help in the efficient disposal of chicken droppings and other waste products. They can include composting or incineration units.

Cost Estimation for Automation Equipment

The cost of automation equipment for a 20,000 chicken farm in Kenya can vary widely depending on several factors. Here’s a breakdown of the estimated costs for each component:

chicken farm in Kenya can vary widely depending on several factors. Here’s a breakdown of the estimated costs for each component:

Feeding Systems

The cost of a feeding system for a 20,000 chicken farm can range from $10,000 to $20,000. This price includes the machinery for automatic feeding, feed storage bins, and  control systems.

control systems.

Water Supply Systems

Automated water supply systems for a 20,000 chicken farm can cost between $5,000 and $10,000. This includes the pumps, filters, and water storage tanks necessary for a continuous supply.

Climate Control Systems

Climate control systems for a 20,000 chicken farm typically range from $15,000 to $30,000. This includes heating, cooling, and ventilation units designed to maintain optimal conditions.

Egg Collection Systems

The cost of egg collection systems can vary from $8,000 to $15,000. This includes conveyors, separators, and collection bins.

Waste Management Systems

Automated waste management systems for a 20,000 chicken farm can range from $7,000 to $12,000. This includes composting units, incinerators, and waste storage solutions.

Total Cost Estimation

Adding up the costs for all the essential automation equipment, the total estimated cost for a 20,000 chicken farm in Kenya can range from $45,000 to $95,000. This figure does not include additional costs such as installation, maintenance, and training.

ROI and Long-Term Benefits

While the initial investment in automation equipment can be substantial, the long-term benefits often outweigh the costs. Automation can lead to:

- Increased production efficiency

- Reduced labor costs

- Improved chicken welfare

- Enhanced food safety and quality

These benefits can contribute to a higher return on investment (ROI) over time.

Conclusion

Investing in automation equipment for a 20,000 chicken farm in Kenya is a strategic move for farmers looking to increase efficiency and productivity. While the initial costs may seem high, the long-term benefits and potential for ROI make it a worthwhile investment. By understanding the various components and their associated costs, farmers can make informed decisions about their automation strategies.